-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

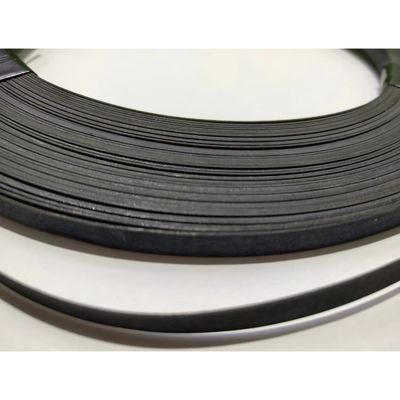

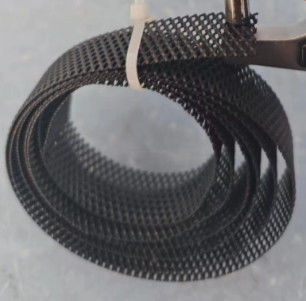

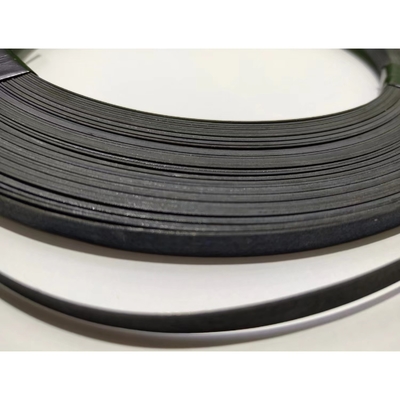

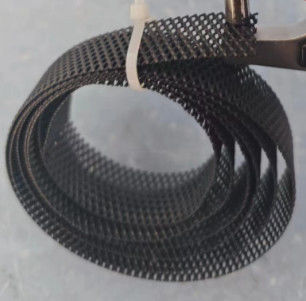

Titanium MMO Ribbon Wire for the cathodic protection:

| Felt Thickness | 0.25~5.0mm | Composition | Titanium Plate And Titanium Mesh |

|---|---|---|---|

| Color | Black | Tempreture | <60 Degree |

| Pt Coating Thickness | 0.5μm - 15 μm | Ph Value | 1-12 |

| Keyword | MMO Coating Titanium Anode | Conductivity | High |

| Shape | Rod | Concentration Range | 1-800ppm |

| Porosity | 70%~90% | Width | 1000-1500mm |

| Application | Electrolysis | Orp | ≥1100mv |

| Unit Cell Specification | 2402*1285*62mm | ||

| Highlight | Titanium Coated Ribbon Wire,Electrodes Anodes Ribbon Wire,Titanium MMO Welding Wire |

||

Descriptions

Titanium MMO Ribbon Wire, also called MMO Titanium Anode, is a high-performance anode used in electrochemical applications. MMO stands for Mixed Metal Oxide, where a titanium substrate is coated with a layer of precious metal oxides to provide excellent electrocatalytic activity and electrical conductivity.

It is also known under several other designations, including:

DSA Anode (Dimensionally Stable Anode)

DSE (Dimensionally Stable Electrode)

PMTA (Precious Metal-coated Titanium Anode)

OCTA (Oxide Coated Titanium Anode)

ATA (Activated Titanium Anode)

NMCA (Noble Metal Coated Anode)

Titanium MMO Ribbon Wire is commonly paired with Titanium Conductor Strips for cathodic protection systems. The oxide coating layer, often made from ruthenium, iridium, or platinum, provides:

Low polarization

Low consumption rate

High electrocatalytic activity

By adjusting the composition of the oxide layer, the ribbon can be adapted to different environments such as seawater, fresh water, and soil, making it one of the most ideal and promising auxiliary anode materials.

Material Specifications

Substrate: Titanium Grade 1 (Gr1)

| Grade | N (Wt%) | C (Wt%) | H (Wt%) | Fe (Wt%) | O (Wt%) | Ti (Balance) |

|---|---|---|---|---|---|---|

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Balance |

Dimensions and Electrical Properties

| Width (mm) | Thickness (mm) | Length/Coil (mm) | Output Current (mA/m) | Cross Section (mm²) | Weight (g/m) | Working Life (years) |

|---|---|---|---|---|---|---|

| 6.35 | 0.635 | 152,000 | 17 | 4.03 | 18.2 | 50 |

| 12.7 | 0.63 | 152,000 | 34 | 8.06 | 36.4 | 50 |

Applications of Titanium MMO Ribbon Wire

Titanium MMO Ribbon Wire is an insoluble DSA anode coated with a high-performance precious metal oxide layer, typically applied using the thermal decomposition method. It is primarily used for impressed current cathodic protection (ICCP) in:

-

Pipeline Protection: Prevents corrosion of the inner walls of pipelines.

-

Tank Protection: Suitable for underground storage tanks, above-ground water tanks, and condensate tanks.

-

Industrial Equipment: Heat exchangers, water treatment equipment, and chemical processing systems.

-

Marine & Infrastructure: Anti-corrosion of ships, bridges, pavements, reinforced concrete structures, and building steel structures.

-

Ground Beds: Continuous horizontal, discontinuous horizontal, and shallow-buried vertical ground beds for cathodic protection systems.

Key Advantages

Long Service Life: Up to 50 years under typical operating conditions.

High Efficiency: Low energy consumption and stable output current.

Corrosion Resistance: Resistant to harsh environments, including seawater and industrial chemicals.

Versatility: Can be used in a wide range of environments, including soil, freshwater, and marine applications.

Titanium MMO Ribbon Wire is one of the most reliable and efficient anode materials for long-term cathodic protection of metallic structures and industrial equipment.