-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

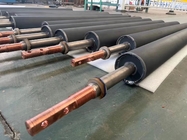

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

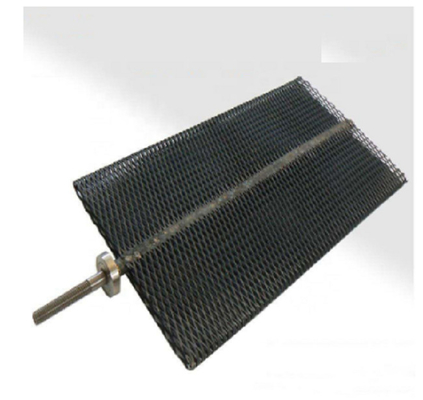

Mmo Coated Titanium Anode For Industrial Wastewater Treatment

| Shape | Mesh, Plate, Basket, Tubular/Assembly | Coating | Ruo2+x / Iro2+x |

|---|---|---|---|

| Current Density | 150-2500A/M2 | Working Temperature | <60℃ |

| Thickness Of Plate /mesh | 0.5-2mm Or As Your Requried | Size | As Your Requirement |

| MOQ | 1Pc Sample Avalible | Coating Thickness | 4-6um Or As Your Requried |

| Highlight | 2mm Titanium Anode Cathode,Electroflotation Titanium Anode Cathode,Iridium Tantalum Oxide Titanium Electrode |

||

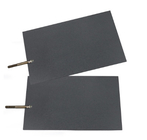

- Base Material: Titanium (Gr1, Gr2, TA1, TA2)

- Shape: Plate,mesh ,tube ,wire,foil ( or customized)

- Working Current: 150-2500 A/m2

- Coating Material: Ru oxide /Ir oxide

- Coating Thickness: 0.2-15μm or as your requried ,generally 4-6um

- Temperature: < 45℃

- PH Value with coating : < 7 Ir-oxide >8 Ru-oxide 7-8 Ir-Ru oxide

Properties: application-specific design, tight adhesion between platinum layer and base titanium material, stable performance, high current and low voltage, even coating.

Application: seawater, horizontal plating, pulse plating, cathode protection. It can be used in acidic or alkaline electroplating solution Etc

Technique : Sand blasting ; Annealing ; Straightening ; Acid Washing ; Brush Plating ; Sintering

![]()

Titanium electrode (anode and cathode)

The electrode is made from a base and a coating.

Among many materials tested, the choice of the support, or substrate as you say in scientific language, has fallen onTitanium.Titanium has in fact the features required in order to receive the coating, to resist the chemically aggressive environments of the processes and it’s suitable for the current’s conduction.Another advantage of Titanium is that it can be worked in a wide range of shapes: sheets, nets, tubes, wires, complex manufactured products etc.The electrode was born from the combination of coating and Titanium, which has afterwards taken different commercial names: DSE - DSA - MMO etc...

Packages and Shipping :

Various Mode of Transportation for You :

1. Air transportation

2. Sea transportation

3. By express mail: DHL, FedEx, EMS, UPS, SF-Express,etc.

Contact me

Aflola

Email:market8@bjcsty.com

Wechat/whatsapp:+86 159 2931 8764

Mobile:+86 159 2931 8764

Skype:Aflola Lee

Facebook:Aflola Lee