-

Titanium Pipe Fittings

-

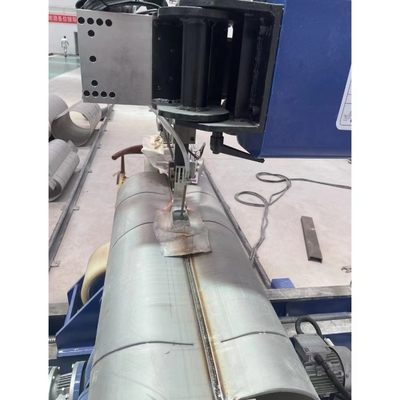

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

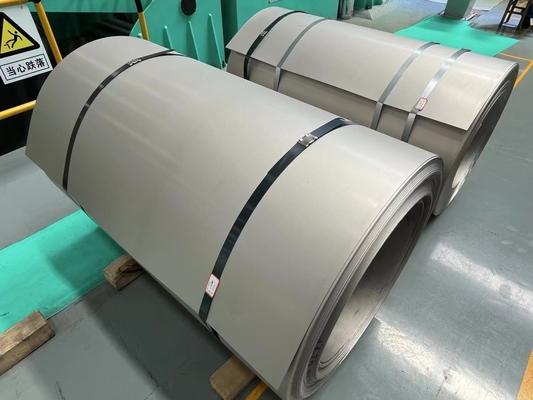

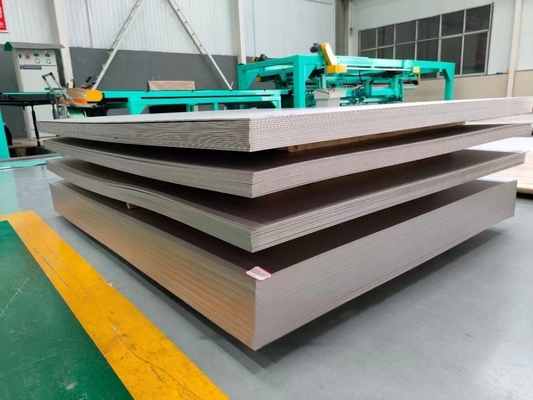

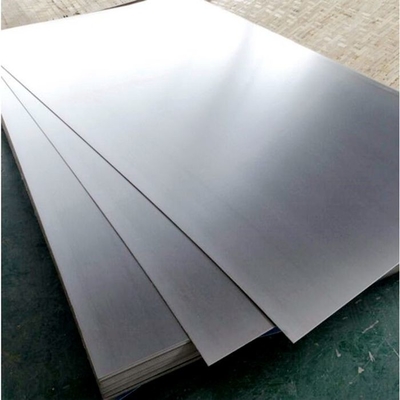

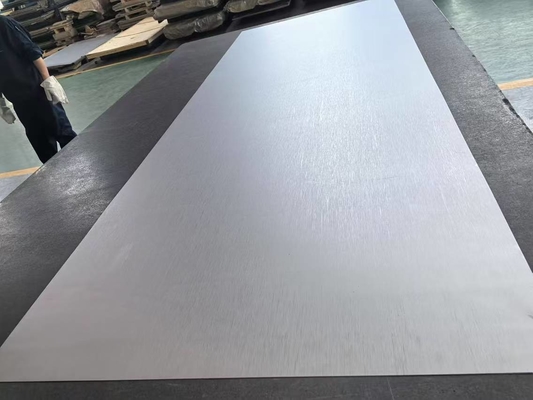

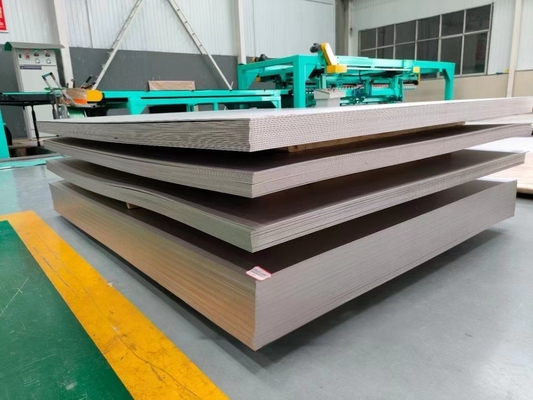

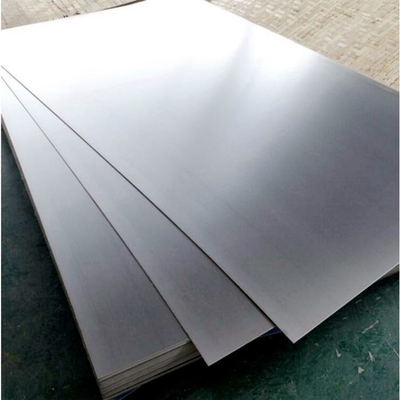

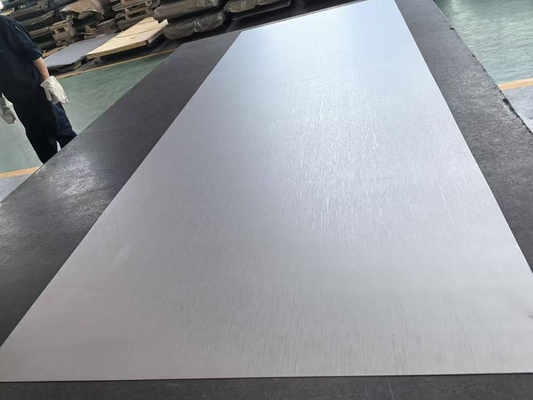

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Alloy Shell Gr5 Welded Shell For Torpedo Aerospace Chemical Industry

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001;2015 |

| Model Number | ASTM |

| Minimum Order Quantity | 50kg |

| Price | $15.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium Alloy | Application | Marine,Aerospace And Defensing |

|---|---|---|---|

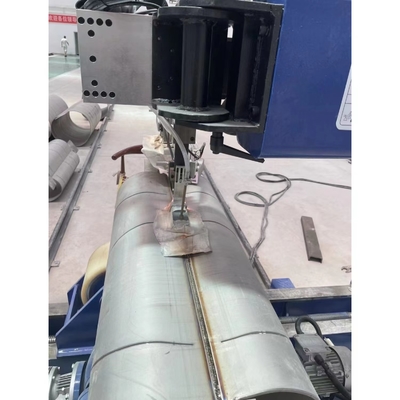

| Standard | AMS 4911/AMS 4900/AMS 4901/AMS 4902/AMS 4914 | Processing | CNC, Forge, Rolling And Welded |

| Origin | Baoji City, China | Other Grade | Titanium Gr5/TA10 |

| Stock | Titanium Gr1/2 Stock | Hardness | Generally In The Range Of 32-38 HRC |

| Yield Strength | 800 MPa | Others Mateiral | Titanium |

| Lengh | 2000-6000mm | Key Word | Ti 6Al4V Alloy Titanium Plates |

| Surface Process | Polished, Anodized, Sandblasted | Techique | Cold Rolled |

| Length | 100mm - 6000mm | Techinique | Cold Rolling Or Hot Rolling |

| Feature | High Elongation Rate | Technique | Cold Rolled |

| Thickness | 0.1mm - 10mm | ||

| Highlight | Marine Titanium Alloy Sheet Shell,Defending Titanium Alloy Sheet,AMS 4911 Titanium Alloy Plate |

||

Description

Titanium exhibits exceptional resistance to acid and alkali corrosion. When immersed in seawater for five years, it shows no signs of rusting — unlike steel, which corrodes and deteriorates rapidly in the same environment. This outstanding corrosion resistance makes titanium alloys ideal for marine applications such as ship hulls and submarine shells.

Titanium submarines offer several advantages:

Superior corrosion resistance: Seawater does not corrode titanium, ensuring long service life.

High-pressure resistance: Titanium submarines can dive 80% deeper than stainless-steel submarines without structural failure.

Non-magnetic properties: Titanium’s non-magnetic nature makes submarines less detectable by magnetic mines, enhancing stealth capabilities.

Deep-diving capability: While steel submarines risk collapse beyond 300 m depth, titanium submarines can safely operate below 300 m and withstand depth charges effectively.

Since the 1960s, titanium has become an irreplaceable material in deep-sea shipbuilding. Russia successfully built the world’s first all-titanium submarine in 1968 and later developed several “Alpha”-class submarines, each using approximately 3,000 t of titanium. Other models, such as the “Shark”-class nuclear submarine and the multipurpose 945 and 988 classes, also feature titanium alloy pressure-resistant hulls, enabling speeds and depths up to 800 m.

Titanium alloys are also widely used in:

Torpedo launch systems and high-pressure gas cylinders

Pumps, valves, pipelines, and propellers

Coolers and structural submarine components

These applications greatly enhance reliability and extend service life in harsh marine environments.

Common Titanium Alloy Grades

| Grade | Features and Applications |

|---|---|

| Ti-6Al-4V | Heat-treatable alloy with excellent strength, weldability, and formability. Used for jet engine compressor blades, impellers, landing gear, fasteners, and structural components. |

| Ti-5Al-2.5Sn | Non-heat-treatable alloy with good crack resistance and weldability. Used for gearboxes, casings, guide vanes, and pipelines. |

| Ti-8Al-1Mo-1V | Non-heat-treatable alloy with good weldability and acceptable forgeability. Used for engine blades, impellers, and airframe structures. |

| Ti-6Al-6V-2Sn | Heat-treatable alloy with excellent forgeability and strength, but poor weldability. Used for fasteners, air inlet control guides, and test components. |

| Ti-13V-11Cr-3Al | Heat-treatable alloy with good formability and weldability. Used in forgings, airframe structures, skins, and fasteners. |

| Ti-2.25Al-11Sn-5Zr-1Mo-0.2Si | Heat-treatable alloy with good crack resistance during forging. Used for high-strength structural parts. |

| Ti-6Al-2Sn-4Zr-2Mo | Non-heat-treatable alloy with good forgeability and weldability. Used in compressor blades, impellers, and structural assemblies. |

| Ti-4Al-3Mo-1V | Heat-treatable alloy with good forgeability and formability. Used for airframe structural components. |

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition (wt %)

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al | V | Mo | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | Ti balance |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | Ti balance |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | Ti balance |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | Ti balance |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | Ti balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | Ti balance |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | — | 0.2–0.4 | Ti balance |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | Ti balance |

LED Flood Light Product FAQ (Unrelated Section)

Commercial CE SAA ROHS Certified Outdoor IP65 Waterproof LED Flood Lights

Available Power: 20 W / 30 W / 50 W / 100 W / 200 W (12 V)