-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

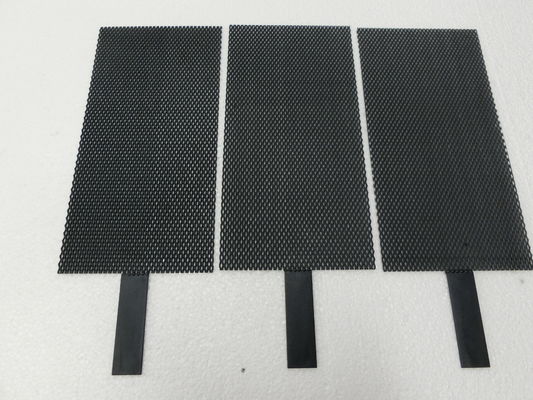

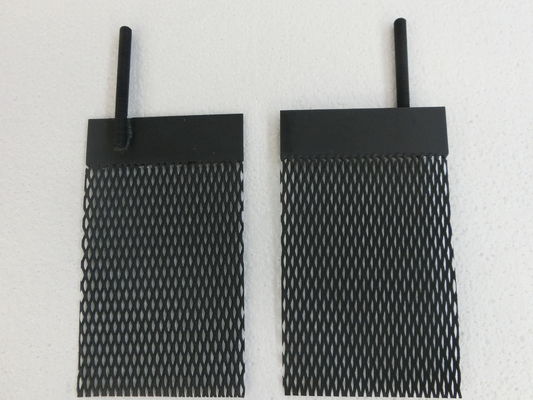

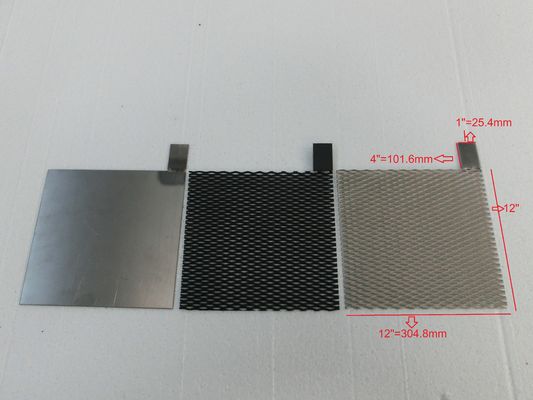

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

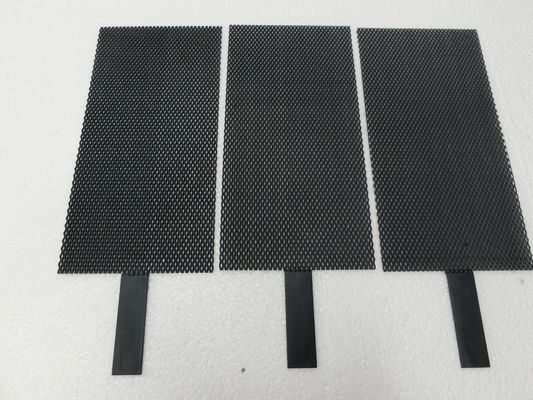

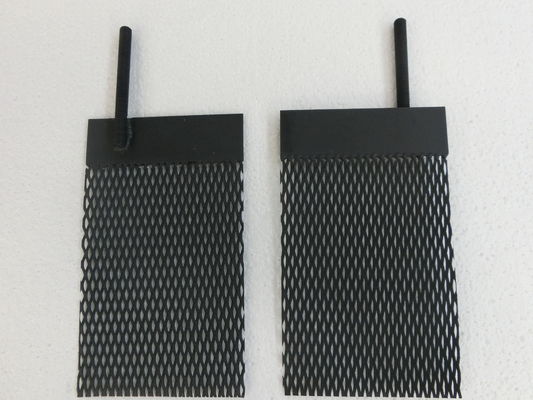

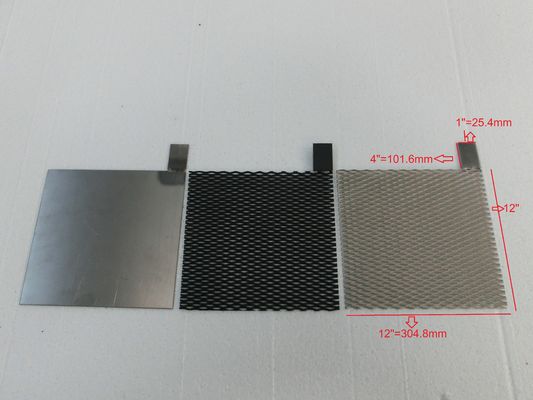

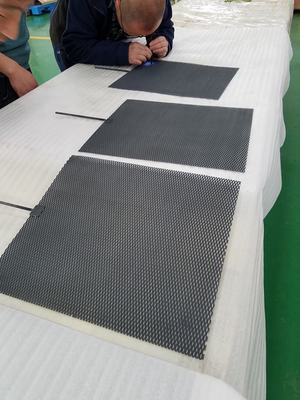

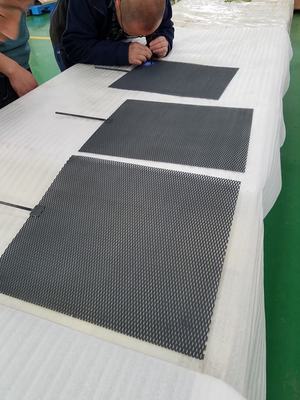

Titanium MMO Sheet For Electrodialysis Water Treatment

| Inner Diameter | 600mm | Size | Customizable |

|---|---|---|---|

| Materials | Titanium | Weight | Lightweight |

| Shape | Rod | Tempreture | <60 Degree |

| Effective Area | 2.7 M² | Electrode Efficiency | ≥ 90% |

| Coating Content | 8g~15g | Unit Cell Voltage | ≤2.96V ( The Current Density5.1kA/m² ) |

| Working Current | 650-800A | Durability | Long-lasting |

| Advantages | Lightweight And Strong | Supply State | Anealed |

| Coating Thickness | 0.76-15 Microns | ||

| Highlight | MMO Coated Titanium Sheet,Electrodialysis Water Treatment Titanium Sheet,Grade 1 Titanium Electrode Plates |

||

Descriptions of Titanium MMO Sheet

Titanium MMO (Mixed Metal Oxide) Sheet is a titanium-based electrode material coated with a layer of mixed metal oxides such as ruthenium, iridium, platinum, or tantalum. It offers excellent electrochemical performance, high durability, and superior corrosion resistance, making it ideal for use in harsh chemical environments. The MMO coating provides excellent catalytic properties for oxygen and chlorine evolution reactions, ensuring long service life and stable performance in various electrolytic processes.

Specifications of Titanium MMO Sheet

Titanium Substrate Composition

| Grade | N (%) | C (%) | H (%) | Fe (%) | O (%) | Ti |

|---|---|---|---|---|---|---|

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Balance |

| Gr2 | 0.03 | 0.05 | 0.015 | 0.30 | 0.25 | Balance |

Regular Coating Types

Platinum: 0.5 μm / 1 μm

Mixed Iridium and Platinum: 0.5 μm / 1 μm

Mixed Ruthenium and Iridium: 6–8 μm

Mixed Iridium and Tantalum: 6–8 μm

Characteristics

Coating: Mixed Ruthenium and Iridium

Chlorine Evolution Potential: < 1.13 V

Polarizability: ≤ 40 mV

Accelerated Life: ≥ 3000 min (under 1000 A/m²)

Anode Weight Loss: ≤ 10 mg

Suitable Working Environment: Solution containing Cl⁻, pH ≤ 7

Coating Contents & Service Life

| Coating Load (g/m²) | Service Life (hours) |

|---|---|

| 8 | > 6,000 |

| 10 | > 8,000 |

| 12 | > 10,000 |

| 15 | > 12,000 |

| 20 | > 15,000 |

Working Parameters

Current Density: < 600 A/m²

Operating Temperature: 40–60 °C

Chlorine Concentration: 30–50 g/L

Polarity Reversal: Suitable

Reversal Frequency: 2–4 hours

Regular Sizes

| Dimensions (mm) | Quantity |

|---|---|

| 63.5 × 150 | 13 pcs/set |

| 64 × 110 | 7 pcs/set |

| 80 × 120 | 1 pcs/set |

| 30 × 183 | 7 pcs/set |

| 80 × 185 | 7 pcs/set |

Applications of Titanium MMO Sheet

Titanium MMO Sheet is widely used in electrochemical and corrosion protection systems, including:

Cathodic protection (CP) systems for pipelines, storage tanks, and marine structures

Electrochlorination and water treatment systems

Electrowinning and electroplating processes

Electrochemical oxidation and reduction reactions

Desalination plants and wastewater treatment systems

Corrosion monitoring and control equipment

Titanium MMO sheets combine the high strength and corrosion resistance of titanium with the excellent catalytic activity of mixed metal oxides, ensuring high performance, long life, and cost efficiency in demanding industrial environments.