-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

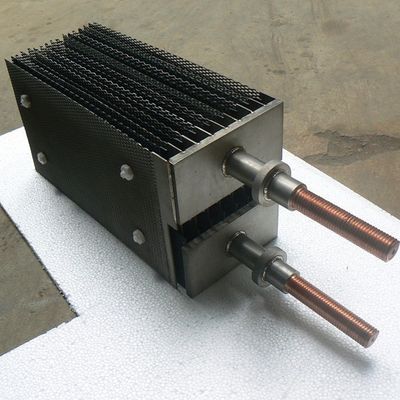

Titanium Sodium Hypochlorite Generator For Water Treatment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Working Temperature | 40-60℃ | Sample | 1.0*50*50mm Sample Size Is Available |

|---|---|---|---|

| Another Name | DSE(Dimensionally Stable Electrode | Durability | Long-lasting |

| Maximum Operating Voltage | 6 V | Operating Life | 3-20 Years |

| Service Life | 20-30years | Wire Diameter | 0.15-0.20mm Is Commonly Used |

| Orp | ≥1100mv | Lifetime | Available For 50,100 Years |

| Type | Mesh /Plate Assembly Or Loose | Weight | Lightweight |

| Usage | Storage Tank | Coating Thickness | 4-6um Or As Your Requried |

| Working Environment | Coke,Soil And Fresh Water,Seawater | ||

| Highlight | Titanium Sodium Hypochlorite Generator,Water Treatment Sodium Hypochlorite Generator,Generator Titanium Electrode |

||

Descriptions

Titanium Sodium Hypochlorite Generator is an electrochemical device used to produce sodium hypochlorite (NaOCl) solution — a powerful and environmentally friendly disinfectant — from common salt (NaCl) and water through electrolysis. The generator uses a titanium-based anode with a mixed metal oxide (MMO) coating, ensuring high efficiency, excellent corrosion resistance, and long service life under continuous operation.

During operation, an electric current passes through the saltwater electrolyte, converting chloride ions into active chlorine, which combines with sodium to form sodium hypochlorite. The titanium anode prevents corrosion and fouling, ensuring stable output and minimal maintenance. This technology provides a safe, on-site, and cost-effective method for producing disinfectant without the need to transport or store hazardous chemicals.

Specifications of Titanium Sodium Hypochlorite Generator

Titanium Substrate Composition

| Grade | N (%) | C (%) | H (%) | Fe (%) | O (%) | Ti |

|---|---|---|---|---|---|---|

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Balance |

| Gr2 | 0.03 | 0.05 | 0.015 | 0.30 | 0.25 | Balance |

Regular Coating Types

Platinum: 0.5 μm / 1 μm

Mixed Iridium and Platinum: 0.5 μm / 1 μm

Mixed Ruthenium and Iridium: 6–8 μm

Mixed Iridium and Tantalum: 6–8 μm

Characteristics

Coating: Mixed Ruthenium and Iridium

Chlorine Evolution Potential: < 1.13 V

Polarizability: ≤ 40 mV

Accelerated Life Test: ≥ 3000 min under current density of 1000 A/m²

Anode Weight Loss: ≤ 10 mg

Suitable Environment: Solutions containing Cl⁻, pH ≤ 7

Coating Load & Service Life

| Coating Load (g/m²) | Service Life (hours) |

|---|---|

| 8 | > 6,000 |

| 10 | > 8,000 |

| 12 | > 10,000 |

| 15 | > 12,000 |

| 20 | > 15,000 |

Working Parameters

Current Density: < 600 A/m²

Operating Temperature: 40–60 °C

Chlorine Concentration: 30–50 g/L

Polarity Reversal: Suitable

Reversal Frequency: Every 2–4 hours

Regular Sizes

| Dimensions (mm) | Quantity |

|---|---|

| 63.5 × 150 | 13 pcs/set |

| 64 × 110 | 7 pcs/set |

| 80 × 120 | 1 pcs/set |

| 30 × 183 | 7 pcs/set |

| 80 × 185 | 7 pcs/set |

Applications of the Titanium Sodium Hypochlorite Generator

-

Drinking Water Disinfection

Used to produce sodium hypochlorite for municipal and rural drinking water systems, effectively killing bacteria, viruses, and microorganisms to ensure safe potable water. -

Swimming Pool Disinfection

Provides continuous on-site generation of hypochlorite for maintaining safe, clean, and algae-free pool water. -

Wastewater Treatment

Applied in wastewater treatment plants for effluent disinfection before discharge, preventing bacterial contamination and protecting the environment. -

Aquaculture

Used to sterilise aquaculture water, eliminating harmful bacteria, viruses, and parasites to ensure healthy aquatic conditions. -

Industrial Applications

Extensively used in industries for metal surface treatment, paper and pulp bleaching, textile bleaching, and other processes requiring controlled hypochlorite generation.

Titanium Sodium Hypochlorite Generators offer long-lasting, energy-efficient, and maintenance-friendly operation — providing a sustainable and safe solution for on-site disinfectant production in water treatment and industrial systems.