-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

MMO Titanium Electrode And Anodes Ruthenium-Iridium Coating

| Place of Origin | China |

|---|---|

| Brand Name | CSTI |

| Certification | ISO9001 |

| Model Number | mixed metal oxides of ruthenium,Iridium,tantalum |

| Minimum Order Quantity | 1 Piece |

| Price | $26.00 - $58.00/ Piece |

| Packaging Details | 1. Packing with moisture-proof paper; 2. Packing with foam plastics in all sides; 3. Packing products in standard wooden cases. |

| Delivery Time | 10~15 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 10000 Piece/Pieces per Month |

| Brand Name | Changsheng Titanium Anode | Substrate | Titanium Gr1 Gr2 |

|---|---|---|---|

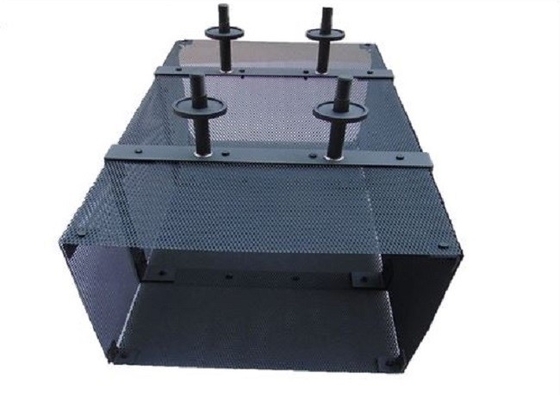

| Coating | Mixed Metal Oxides Of Ruthenium,Iridium | Shape | Plates, Meshes, Rods, Or Custom-designed |

| Current Density | Typically Between 10~300 A/m²,depends On The Application, Electrolyte Composition, And Desired Electrochemical Reaction | Coating Thickness | Typically In The Range Of 5 ~ 20 Microns,depending On The Application And Manufacturer |

| Highlight | Ruthenium Iridium Coating Titanium Electrode,MMO Titanium Electrode And Anodes,Gr1 titanium mesh Electrode |

||

Description of MMO Titanium Anode Ruthenium-Iridium Coated

MMO (Mixed-Metal Oxide) titanium anodes with ruthenium-iridium coating are advanced and highly efficient electrochemical electrodes used in various applications. Here's description of MMO titanium anode with ruthenium-iridium coating:

1.Base Material: Titanium, which provides excellent mechanical strength, lightweight properties, and resistance to corrosion in various environments. Titanium is widely used in electrochemical applications due to its compatibility with different electrolytes.

2.Mixed-Metal Oxide Coating: The MMO coating on the titanium anode consists of a mixture of various metal oxides, with ruthenium and iridium being the key components.

3.Electrochemical Properties: The ruthenium-iridium coating enhances the electrochemical performance of the titanium anode. It improves the anode's catalytic activity, increases the current-carrying capacity, and provides stability during the electrochemical reactions.

4.Corrosion Resistance: The ruthenium-iridium coating significantly enhances the corrosion resistance of the MMO titanium anode. It protects the underlying titanium substrate from degradation, even in aggressive environments, such as those containing chloride ions or acidic solutions.

5.High Current Efficiency: The combination of the titanium base material and the ruthenium-iridium coating results in high current efficiency during electrochemical processes. This means that a greater portion of the applied electrical current is effectively utilized for the desired electrochemical reactions, leading to improved efficiency and reduced energy consumption.

6.Longevity and Durability: The MMO titanium anode with a ruthenium-iridium coating offers excellent durability and long service life. The robust corrosion resistance of the coating helps prevent deterioration, allowing the anode to withstand harsh conditions and extended operational periods.

7.Application Versatility: MMO titanium anodes with a ruthenium-iridium coating find use in a wide range of electrochemical applications, including water treatment, chlor-alkali production, electroplating, cathodic protection, and electrolytic synthesis. They provide reliable and efficient performance in diverse electrochemical processes.

Specification of MMO Titanium Anode Ruthenium-Iridium Coated

The specifications of an MMO (Mixed-Metal Oxide) titanium anode with a ruthenium-iridium coating can vary depending on the specific application. However, here are some common specifications:

| Base Material | Titanium (Grades 1 or 2) |

| Coating Composition |

Mixed-Metal Oxide (MMO) Coating: Consists of a combination of metal oxides, including ruthenium and iridium. The specific composition and ratio may vary depending on the desired electrochemical performance and application requirements. |

| Coating Thickness |

Typically in the range of 5 ~ 20 microns depending on the application and manufacturer. Thicker coatings provide better durability and extended service life. |

| Current Density |

typically between 10~300 A/m². The recommended current density depends on the application, electrolyte composition, and desired electrochemical reaction |

| Connection Type | threaded studs, bolt holes, or welded tabs, to facilitate easy and secure installation |

| Dimensions and Shape |

plates, meshes, rods, or custom-designed geometries depending on the application requirements. The dimensions are typically specified based on the size and configuration of the electrolytic cell or system. |

Ruthenium-Iridium coating (Ru-Ir)

![]()

Advantages of Ruthenium-IridiumTitanium anode:

(1) The anode size is stable, and the distance between the electrodes does not change during the electrolysis process, which can ensure that the electrolysis operation is performed under the condition that the cell voltage is stable;

(2) The working voltage is low, so the power consumption is small, and the DC power consumption can be reduced by 10% - 20%;

(3) Long working life;

(4) It can overcome the problem of dissolution of graphite anode and lead anode, avoiding contamination of electrolyte and cathode products, and thus improving the purity of metal products;

(5) can increase the current density;

(6) In the production of chlor-alkali, after the titanium-coated ruthenium electrode, the product quality is high, the chlorine gas has high purity, does not contain CO2, and the alkali concentration is high, which can save steam for heating and save energy consumption;

(7) Strong corrosion resistance;

(8) The short circuit problem after the deformation of the lead anode can be avoided, thereby improving the current efficiency;

(9) The titanium electrode is light in weight and can reduce labor intensity;

(10) The shape is easy to manufacture and can be highly accurate;

(11) The substrate can be used repeatedly.

Application areas of Ruthenium-IridiumTitanium anode:

Ruthenium-Iridium-Titanium (Ru-Ir-Ti) anodes are advanced and highly efficient anode materials commonly used in various electrochemical applications. Here are some application areas where Ru-Ir-Ti anodes find use:

1.Electrochemical Chlorination: Ru-Ir-Ti anodes are extensively employed in electrochemical chlorination systems, such as seawater chlorination for marine and offshore applications. They exhibit excellent stability, high current efficiency, and resistance to corrosion, making them suitable for generating chlorine and other oxidizing agents.

2.Water Treatment: Ru-Ir-Ti anodes are utilized in various water treatment applications, including disinfection, wastewater treatment, and swimming pool chlorination. They provide reliable and long-lasting performance in electrolytic processes, effectively eliminating pathogens, reducing organic compounds, and maintaining water quality.

3.Electroplating: Ru-Ir-Ti anodes are preferred in electroplating operations where high durability and consistent performance are required. They ensure uniform plating, reduce the formation of undesirable byproducts, and provide better control over the plating process. Ru-Ir-Ti anodes are suitable for a range of metal plating applications, including gold, silver, nickel, and chrome plating.

4.Electrowinning and Electrorefining: In the mining and metallurgical industries, Ru-Ir-Ti anodes are used for electrowinning and electrorefining processes. These anodes facilitate the deposition or extraction of metals from electrolytes, such as copper, zinc, nickel, and precious metals like gold and silver. Their high efficiency and resistance to corrosion contribute to improved productivity and cost-effectiveness.

5.Electrodialysis: Ru-Ir-Ti anodes play a vital role in electrodialysis systems, which are used for desalination, brine purification, and ion exchange applications. They help remove impurities, separate ions, and control pH levels in the electrochemical cells, ensuring efficient and reliable operation of the electrodialysis process.

6.Electrochemical Synthesis: Ru-Ir-Ti anodes are utilized in various electrochemical synthesis reactions, including organic and inorganic compound synthesis. They enable selective and controlled reactions, including oxidations, reductions, and electrolytic polymerizations, by providing stable and efficient electrochemical conditions.

Tag: MMO Titanium Electrode and anodes, mmo anode; titanium anode