-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

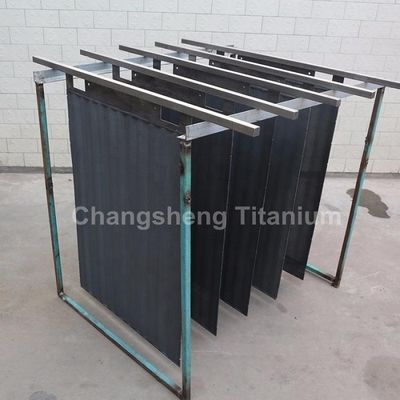

Lead Dioxide Coated Titanium Electrode Plate PbO2 Gr2 Anode electrodeposition of copper, nickel, cobalt and zinc

| Place of Origin | China |

|---|---|

| Brand Name | CSTI |

| Certification | ISO9001 |

| Model Number | PbO2/Lead dioxide coated titanium anode |

| Minimum Order Quantity | 1 Piece |

| Price | $100.00 - $1,000.00/ Piece |

| Packaging Details | 1. Packing with moisture-proof paper; 2. Packing with foam plastics in all sides; 3. Packing products in standard wooden cases. |

| Delivery Time | 10~15 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 100000 Set/Sets per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Substrate | Gr1 /Gr2 As Basement | Model Number | CSTY-PbO2 Coated Anode |

|---|---|---|---|

| Coating | PbO2/Lead Dioxide | Shape | Mesh /Plate Assembly Or Loose |

| Application | Electrodeposition Of Copper, Nickel, Cobalt And Zinc | Ti Content (%) | 99% |

| Surface Hardness(HRC) | 11 | The Conductivity Of Anode | 4--5*10-5Ω |

| Highlight | PbO2 titanium cathode plate,Lead Dioxide Coated Titanium Cathode Plate,gr2 lead dioxide anode |

||

PbO2 coated titanium anode introduction:

Lead Dioxide (PbO2) coated Titanium (Ti) electrode plate is commonly used as an anode for electrodeposition processes of metals like copper, nickel, cobalt, and zinc. The combination of PbO2 and Ti makes for a highly corrosion-resistant and durable electrode that can withstand the harsh chemical environments of electroplating.

The use of PbO2 as a coating material for the Ti electrode plate provides several benefits. PbO2 is an excellent conductor of electricity, which allows for efficient transfer of electrons during the electroplating process. Additionally, PbO2 is highly resistant to corrosion, which helps to extend the lifespan of the electrode and reduce the need for frequent replacement.

Gr2 is the grade designation for commercially pure Titanium (CP Ti), which is commonly used in industrial applications due to its excellent corrosion resistance and biocompatibility. Using a CP Ti substrate as the base for the PbO2 coating provides a durable and reliable electrode for use in electroplating processes.

1. Product specifications: processing according to drawings

2. Anode life: more than 2 years

3. Use coating category: titanium-based lead dioxide anode

4. Electrochemical performance and life test (reference standard HG/T2471-2007 Q/CLTN-2012)

Technical indicators of PbO2 coated titanium anode

(1) The anode plate adopts a titanium-based intermediate layer coated with precious metals, α-pbO2 and β-PbO2, and the conductive rod adopts Titanium copper composite rod: the anode plate and the conductive rod are connected by welding.

(2) The thickness of the base titanium mesh is 2mm, the thickness of the coating layer is not less than 0.6mm on one side, and the thickness of the finished product is not less than 3.5mm; the surface of the board should be flat, and there should be no inclusions such as delamination and cracks on the surface of the finished product.

(3) The verticality of the board surface: the error of the top and bottom of the board surface is less than ±6mm

(4) Life: corrosion resistance, bending resistance, lifespan of more than 2 years

(5) After processing, the plane tolerance and curved surface tolerance are required to be less than ±5mm, and the diagonal

tolerance is less than 3mm

(6) Processing strictly in accordance with the drawings

| Item |

coating thickness mm |

Oxygen evolution potential V | Test Conditions | CL-content |

Lifetime h |

| lead dioxide coated titanium anode | 3 | <1.73 | 15% H2SO4 | <2g/L | >500h |

![]()

Customer feedback

Actual use data of secondary copper removal with an annual output of 2000 tons:

Project name: Lead dioxide coated titanium anode used in secondary copper removal production system

Purpose of use: Lead dioxide coated titanium anode is cost-effective in secondary copper removal system and lead anode

Working condition: PH=1.5

Sulfuric acid: 170g/L

Copper ion: 50-55g/L

Bone glue: 5-7g/L

Temperature: 60°C

Pole spacing: 55mm

Chloride ion: <50ppm

|

Anode types |

current density A/m2 |

Cell voltage V |

Current efficiency |

lifetime |

|

Lead anode |

180~210 |

2~2.1 |

89%~91% |

12months |

|

PbO2 coated titanium anode |

180~210 |

1.9~2.1 |

92%~94% |

>24months |

Product Advantages

Comparison of PbO2 coated titanium anode and traditional lead anode:

A. No pollution to the electrolyte, no complicated lead removal system expenses.

B. The external dimensions are fixed, and the anode will not deform due to self-dissolution, which will affect the appearance of the cathode product.

C. Since the titanium matrix is not consumed during the electrolysis process, the titanium matrix can be recoated repeatedly

D. High current efficiency. At present, the current efficiency of the titanium anode produced by our company can reach 93-95%, while the current efficiency of the traditional lead anode is only 89-91%.

E. The tank voltage is low. The voltage of the titanium-based lead dioxide anode tank produced by our company is 2%-3% lower than that of the lead anode tank, and the power saving effect is very obvious.

F. The cathode product is of high quality. Because the solution does not contain lead, lead pollution is eliminated.

G. It can work with high current. The lead anode will quickly dissolve under high current. The titanium-based lead dioxide anode can withstand currents above 500A/m2, which is suitable for short-term and large-scale production requirements.

H. Reduce labor intensity and improve working environment. Lead anodes have the disadvantages of heavy weight, soft material, thinning during production, and easy deformation. As a result, the cathode nickel plates are also easy to deform. Workers often need flat plates during production, which is labor-intensive. At the same time, because lead is a heavy metal, it is highly toxic, affects the human nervous system and seriously pollutes the environment. At the same time, barium carbonate used for lead removal is also highly toxic.

In general, titanium-based lead dioxide anode saves 8% of energy consumption than lead anode electrowinning activity; higher price of high-quality cathode products. The combined benefits of multiple advantages will be very impressive.

Lead Dioxide Coated Titanium Electrode Plate PbO2 Gr2 Anode electrodeposition of copper, nickel, cobalt and zinc Application Case

Lead Dioxide coated titanium electrode plates (PbO2/Ti) are commonly used as anode materials for various electrochemical processes, including electrodeposition of metals such as copper, nickel, cobalt, and zinc. The use of PbO2/Ti anodes has several advantages, including high stability, corrosion resistance, and high current efficiency.

In the case of electrodeposition of copper, nickel, cobalt, and zinc, PbO2/Ti anodes are preferred due to their high oxygen evolution potential and low overpotential for metal deposition. This results in higher current efficiency and reduced energy consumption during the electroplating process. Additionally, PbO2/Ti anodes have a longer lifespan compared to other anode materials, leading to reduced maintenance costs.

The process of electrodeposition involves the reduction of metal ions from a solution onto a substrate surface under the influence of an electric field. During this process, the anode material is oxidized, leading to the formation of oxygen gas. PbO2/Ti anodes have a high oxygen evolution potential, which reduces the formation of hydrogen gas and other undesirable side reactions. This results in a cleaner and more efficient electroplating process.

Overall, PbO2/Ti anodes are a reliable and cost-effective solution for electrodeposition of metals such as copper, nickel, cobalt, and zinc. Their high stability, corrosion resistance, and high current efficiency make them an ideal choice for a wide range of electrochemical applications.