-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

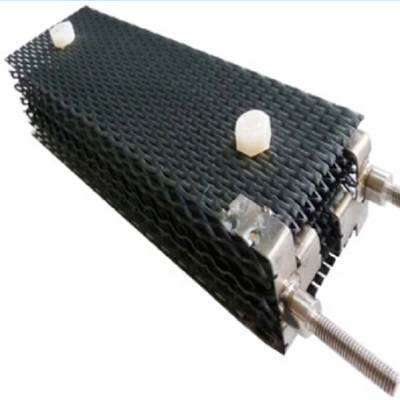

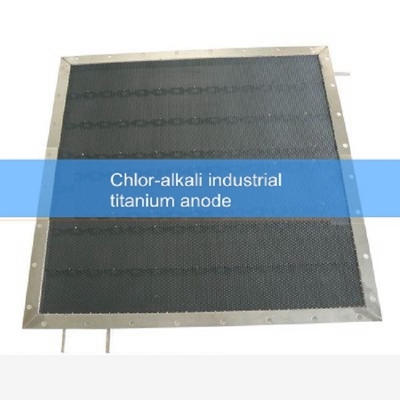

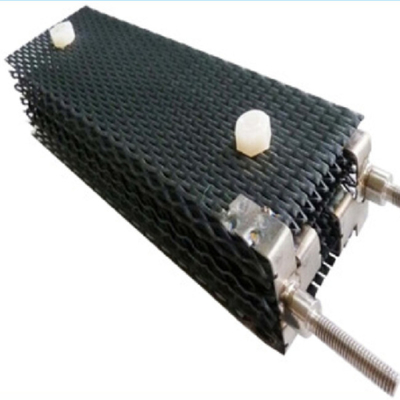

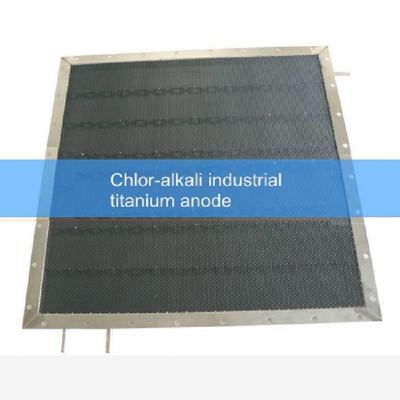

Titanium Gr2 Electrode Plate 4um To 6um For Chlor Alkali Chloride Industry Anode

| Place of Origin | China |

|---|---|

| Brand Name | CSTI |

| Certification | ISO9001 |

| Model Number | mmo coated titanium anode for chlor-alkali Chlorate industry |

| Minimum Order Quantity | 1 Piece |

| Price | $20.00 - $500.00/ Piece |

| Packaging Details | 1. Packing with moisture-proof paper; 2. Packing with foam plastics in all sides; 3. Packing products in standard wooden cases. |

| Delivery Time | 10~15 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 1000 Piece/Pieces per Month |

| Substrate | Gr1 /Gr2 As Basement | Coating | Ru-Ir Oxide |

|---|---|---|---|

| Shape | Mesh /Plate Assembly Or Loose | Application | Chlor-alkali Chlorate Industry |

| Hydrochloric Acid Concentration | 15% | Coating Thickness | 4-6um As Your Requried |

| Ampere Density | <1500A/m2 | Working Temperature | 40-60℃ |

| Highlight | gr2 mmo coated titanium anodes,4um mmo coated titanium anodes,6um electrode anode |

||

Good Quality best price mmo coated titanium anode for chlor-alkali Chlorate industry

Chlor-alkali industrial production process is often accompanied by strong corrosive media and strong metal corrosive media such as chlorine gas, hydrochloric acid, ClO-, so the selection of suitable materials is the primary condition for controlling corrosion and prolonging service life in the research and development of electrode materials for chlor-alkali industry, the formula ratio of electrode coating was adjusted and optimized. Iridium and tin were added to the Ru coating, which reduced the potential of chlorine evolution and increased the service life of the electrode.According to the characteristics of chlor-alkali industry, all welding parts and accessories are made of corrosion-resistant materials to ensure that the anode is corroded from the parts during improper operation, thus affecting the use of the anode

Specification

Working Parameter |

Current density ≤1500A/m2Temperature:40-50℃

|

Coating type |

Mixing Ru oxideMixing Ru-Ti oxide |

Coating thickness |

6-8micron or as your requried |

![]()

Our Advantage

1. Several metal elements ere added to make the coating evenly distributed and fused, which reduced the material cost of the anode,reduced the chlorination overpotential, reduced the tank pressure, and saved energy consumption

2. According to the characteristics of the chlor-alkali industry, the electrode, welding parts and accessories are made

of corrosion-resistant materials and processed in multiple processes to avoid corrosion from vulnerable parts and lead to electrode corrosion

3. After the anodic oxide coating fails or reaches the service life, the anodic repair and recoating technical services can be provided

Advantages of titanium products

.High antiseptic property

·High current efficiency.

·Lasting working life.

·Base material can be recycling when electrodes lose activity.

·High electric current density and high productivity.

·Lightweight electrodes.

Application

Ruthenium iridium titanium anode for chlor-alkali industry parameter

Current density <500A/M2

Temprature 40-50℃

Strengthen weight loss mg≤10

Polarization rate ≤30mv

Chloride potential:<1.13v

Hydrochloric acid concentration :15%

Reversal frequency 2-4hours

Size: 63.5*150mm 13pcs as one unit

64*110mm 7pcs as one unit

8*120mm /30*183mm or as your requried

Why Choose Us

Quality Guarantee:

(1) Main quality indicators: titanium substrate, precious metal ratio, accelerated life, coating binding force to the titanium

substrate(coating adhesion)

(2) With advanced technology & equipment, abundant experiences and skilled workers,during the production of Titanium Anode, each process must be strictly supervised and tested, including the surface treatment of titanium material, coating quality, coating evenness, coating binding force to the titanium substrate(coating adhesion) and so on.

(3) We have own R&D, Production and Sales department, we always struggling to supply the product with the most excellent quality and the most favorable price and supply the most efficient service.

(4) Each production process are looked at to make sure the specifications and performance are qualified.

(5) Strict Pre-delivery inspection for each order,only when all specifications and performance are met,the product is allowed to be sent out.

Our company :

In the year 2001, set up the forging workshop.

In 2006, registered for Changsheng Titanium Co.

In 2008, started the global business, established Changtai Metals Trading Co.

In 2008, worked with alibaba.com, and to be the golden supplier of alibaba.

In 2010, researched and developed the technology of big seamless titanium tube.

In 2012, finished the trial production of big seamless titanium tube sucessfully, and applied for the national patent.

In 2013, made mass production of big seamless titanium tube.

In 2014, developed the technology of Grade 5 tube, introduced Germany production equipment.

In 2014, enlarged the production line of customized parts, made titanium radiators and heat exchangers for Canada Saltswork and American Ural Company.

In 2015, finished the trial production of Grade 5 tubes, and started to make mass production.

In 2016, set up foreign sales team in Xi'an City.

In 2017, enlarged the production of tube.

In 2018, enlarged the production of plate and anode.

In 2019, we focus on India market, plan to attend two exhibitions India in September & November.

FAQ

1. Can you give a quotation as per the product picture on your website?

Answer: Our anodes are non-standard products, most of them are in accordance with the requirements of the customer's specific requires. The application industries and countries are different, so please let your engineers or your customer's engineers to provide a specific size, anode working environment, usage, current density and life expectancy, so we can offer you specific price.

2. What is your internal inspection procedure, how do you inspect your products?

Answer: the internal inspection procedures, There are 6 steps: Material, mechanical processing, surface treatment, coating, cable connection and packing.

Every step has responsible leader, the inspector checks carefully every step with professional records, operation files, check subjects and performing programs. Once problems are checked out, steps will be taken to make up.

3. Do you have any certificate for your testes from any third party (like SGS, etc)? Or has any third party inspection company has ever tested your anodes and reported?

Answer: yes, we do have some test certificates from famous third party, like St Louis testing laboratory and china classification society etc.

4. The wooden case is too heavy; can I have other packing method such as carton box to save the freight cost?

Answer: Wooden cases are do heavy, but as per our years of export experience, carton box can make damage for the anode. Though wooden cases are heavy, but it will not damage the anode

Tag: Titanium Anode, MMO coated titanium anode, Chlor-Alkali Chlorate industry