-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

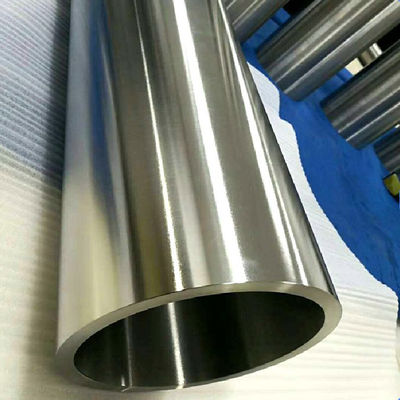

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

GR5 Titanium Alloy Seamless Pipe For Aviation Oil Pipeline Aircraft Auxiliary Oil Pipe

| Certifications | ASTM B338, ASME SB338 | Outer Diameter | 10-89mm |

|---|---|---|---|

| Tubes Type | Seamless Tubes, Welded Tubes | Keyword | Aviation Oil Pipeline |

| Surface Treatment | Polished, Anodized, Brushed, Sandblasted | Sizes | Od30*3mm , Od52*6mm, Od50*5mm, Od59*5mm |

| Length | Customizable | Package | Wooden Case |

| Highlight | Aviation Oil Pipeline Seamless Pipe,Aircraft auxiliary oil pipe Seamless Pipe,GR5 Titanium Alloy Seamless Pipe |

||

1. Why use titanium alloy to make aviation fuel pipes?

Titanium alloy has the following advantages, which are particularly suitable for the aviation field:

Light weight: about 40% lighter than steel, weight reduction is the key to aircraft design.

Super corrosion resistance: can resist aviation fuel, water vapor, and salt spray corrosion.

High strength: The strength is close to that of steel, much higher than aluminum, and has strong pressure resistance and explosion resistance.

High and low temperature resistance: can withstand extreme environments from -250°C to 600°C.

Good fatigue performance: long-term work in high pressure and vibration environment, not easy to crack and fail.

Extremely long life: the service life is much longer than traditional carbon steel or aluminum alloy fuel pipes.

Therefore, titanium alloy fuel pipes are mostly used for:

Aircraft main fuel pipelines, engine peripheral fuel pipelines, and internal pipelines of high-end refueling equipment.

2. Common materials for titanium alloy aviation oil pipes

Material code Full name Characteristics

Ti-6Al-4V Titanium-6% aluminum-4% vanadium alloy Most commonly used, high comprehensive strength,

good corrosion resistance, suitable for molding

Ti-3Al-2.5V Titanium-3% aluminum-2.5% vanadium alloy More suitable for cold processing and thin-walled oil pipes

Gr.2 pure titanium Industrial pure titanium Average strength, but excellent corrosion resistance, suitable for low-pressure systems

3. Titanium alloy oil pipe manufacturing process

Seamless titanium pipe manufacturing: hot extrusion + cold rolling/cold drawing to ensure that the pipe wall is uniform and defect-free.

Welded titanium pipe manufacturing: laser welding after titanium strip forming, suitable for large diameter pipes.

Surface treatment:

Pickling to remove oxide layer

Passivation treatment to prevent later corrosion

Precision size control:

Pipe diameter tolerance is generally controlled within ±0.1mm

Pipe wall thickness tolerance ±10%

4. Typical performance indicators (taking Ti-6Al-4V as an example)

Tensile strength: ≥895 MPa

Yield strength: ≥828 MPa

Elongation: ≥10%

Hardness: 280~340 HV

Density: about 4.43 g/cm³ (40% lower than steel)

5. SIZE DETAILS

| Model No. | OD (mm) | THICKNESS (mm) | GRADE | STANDARDS | REMARKS |

| CS6-10/1.0 | 10 | 1 | Ti-6Al-4V | AMS 4943 / ASTM B348 | Small-diameter fuel circuit |

| CS6-12/1.2 | 12 | 1.2 | Ti-6Al-4V | AMS 4944 / ASTM B861 | Aircraft auxiliary fuel pipe |

| CS6-16/1.5 | 16 | 1.5 | Ti-6Al-4V | AMS 4945 / ASTM B338 | High-pressure fuel main pipe |

| CS6-19/2.0 | 19 | 2 | Ti-6Al-4V | AMS 4945 / ASTM B861 | Engine fuel distribution pipe |

| CS6-25/2.5 | 25 | 2.5 | Ti-6Al-4V | ASTM B861 / GB/T 3623 | Fuel distribution main pipe |

| CS6-32/2.5 | 32 | 2.5 | Ti-6Al-4V | ASTM B861 | Airport ground refueling pipeline |

| CS6-38/3.0 | 38 | 3 | Ti-3Al-2.5V | ASTM B862 | Heavy-duty high-pressure pipeline |

| CS6-50/3.5 | 50 | 3.5 | Ti-6Al-4V | AMS 4943 / ASTM B861 | Refueling bridge system main pipe |

| CS6-63/4.0 | 63 | 4 | Ti-6Al-4V | ASTM B861 | Airport oil storage system supporting |

| CS6-89/4.0 | 89 | 4 | Ti-6Al-4V | GB/T 3624 / ASTM B861 | High-flow oil main pipe |

6. Application examples of titanium alloy oil pipes

Boeing 787 fuel system: Ti-6Al-4V oil pipes are widely used.

Airbus A350 engine accessory oil pipes.

Military tanker and fighter fuel main delivery pipelines.

Airport refueling bridge high-end system (high corrosion resistance and fatigue resistance requirements).