-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

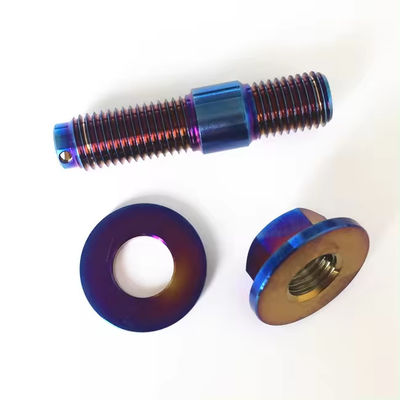

Titanium Fasteners M6 M8 M10 PVD Blue Rainbow Flange Taper Cap Countersunk

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001;2015 |

| Model Number | DIN912 DIN 7991 ISO 7380 |

| Minimum Order Quantity | 200pcs |

| Price | USD2.8/pc |

| Packaging Details | Stardard export package |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,paypal |

| Supply Ability | 2000pcs/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Standard | DIN, ANSI, ISO, JIS, GB | Technique | Forging, Rolled, CNC Turning, Milling |

|---|---|---|---|

| Dimensions | M1-M30 Or Customised | Application | Aerospace, Automotive, Medical, Marine, Construction |

| Packing | Wooden Box Or Carton Box | Color | Normal, Anodizing |

| Delivery | Within 7-25 Days | Custom Size | Workable |

| Temperature Resistance | High | Type | Screws, Bolts, Nuts, Washers, Etc. |

| Keywords | Titanium Bolts | Grade | Grade 5, Ti-6al-4v |

| Strength | Grade 2, Grade 5, Grade 7, Grade 23 | Sample | Availabe |

| Durability | High | ||

| Highlight | M10 Titanium Fasteners,M6 Titanium Fasteners,M8 Titanium Fasteners |

||

Introduction

Titanium alloy has the advantages of being lightweight, having high specific strength, and excellent corrosion resistance. Therefore, it is widely used in the automotive industry, especially in the engine system where titanium alloy bolts are frequently applied. Using titanium bolts for engine components provides benefits such as reduced weight, improved strength, and enhanced performance. As a result, titanium fasteners are extensively used across a wide range of industries.

Specification

| Item | Description |

|---|---|

| Product Name | Titanium Fasteners / Hardware |

| Material | Pure Titanium, Titanium Alloy |

| Grade | Gr5 (Ti-6Al-4V) / Gr2 / Gr7 / Gr9 |

| Size Range | M3–M50, Length 6–300 mm (Non-standard or special sizes available upon request) |

| Surface Finish | Polished, Anodizing, PVD Coating |

| Color Options | Black, Gray, White, Yellow, Red, etc. |

| Logo | Customizable according to customer requirements |

| Applications | Aerospace, Marine, Bicycle, Motorcycle, Automotive, Medical, Chemical, Wheelchair, Sports Equipment, Anchors, Weapons, etc. |

Mechanical Properties

| Property | Specification |

|---|---|

| Thread Type | Rolled thread for better fatigue resistance and to prevent galling (instead of cut thread) |

| Tensile Strength | 895–1000 MPa (Heat Treated) |

| Yield Strength | 828–925 MPa (126,000–134,000 psi) |

| Hardness | 30–40 HRC |

| Shear Strength | 500–550 MPa |

| Elongation | 14–18% |

| Working Temperature | Up to 500°C |

Applications

-

Aerospace Field

The lightweight, high-strength, and corrosion-resistant characteristics of titanium screws make them ideal for use in aircraft engines, fuselages, and structural assemblies. -

Medical Field

Titanium screws are biocompatible and non-allergenic, making them suitable for medical applications such as implants, bone nails, and surgical devices. -

Sports Equipment

Due to their strength and low weight, titanium fasteners are widely used in premium sports equipment such as bicycles, golf clubs, and racing gear. -

Electronics

Titanium’s durability and corrosion resistance make it suitable for the assembly of electronic devices like mobile phones, tablets, and precision instruments.