-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

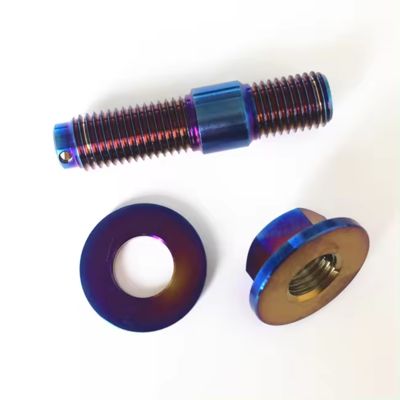

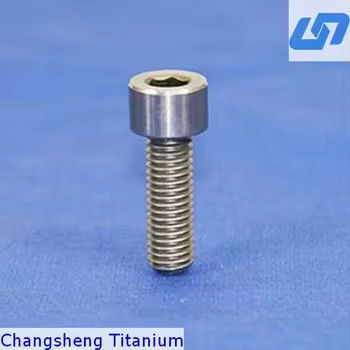

Titanium Flange Bolt DIN 6921 for automobile

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Origin | Baoji, Shaanxi, China | Low Thermal Conductivity | Low Thermal Conductivity |

|---|---|---|---|

| Processing | CNC | Weight | Lightweight |

| Warranty | 5years | Application | Industrial Equipment |

| Type | Screws, Bolts, Nuts, Washers, Etc. | Use | Connection Pipe And Machine Equipment |

| Strength | High Strength | Packing | Wooden Box Or Carton Box |

| Material | Titanium | Rust Proof | Rust Proof Properties |

| Custom Size | Workable | Versatility | Suitable For Various Applications |

| Heat Resistance | High | ||

| Highlight | TC4 Titanium Alloy Bolts,M6 Titanium Alloy Bolts,Stamping titanium bike bolts |

||

Descriptions

Titanium Flange Bolt DIN 6921 is a high-performance fastener designed to secure two or more components together. It features a hexagonal head with an integrated flange, which provides a larger bearing surface to evenly distribute the clamping force.

These bolts are commonly used in applications where corrosion resistance and weight reduction are critical, such as in the automotive, marine, aerospace, and bicycle industries. Despite their higher cost compared to conventional steel bolts, titanium hexagon flange bolts offer superior performance, durability, and an extended range of applications that cannot be replaced by ordinary fasteners.

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition

| Grade | Fe Max | O Max | N Max | C Max | H Max | Pd Max | Al Max | Va Max | Ni Max | Mo Max | Ti Balance |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.2 | 0.18 | 0.03 | 0.08 | 0.015 | – | – | – | – | – | Balance |

| Gr2 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | – | – | – | – | – | Balance |

| Gr4 | 0.5 | 0.4 | 0.05 | 0.08 | 0.015 | – | – | – | – | – | Balance |

| Gr5 | 0.4 | 0.2 | 0.05 | 0.08 | 0.015 | – | 5.5-6.7 | 3.5-4.5 | – | – | Balance |

| Gr7 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12-0.25 | – | – | – | – | Balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | 2.5-3.5 | 2.0-3.0 | – | – | – | Balance |

| Gr12 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | 0.6-0.9 | 0.2-0.4 | – | – | – | Balance |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | 5.5-6.5 | 3.5-4.5 | – | – | – | Balance |

Applications

Titanium Flange Bolt DIN 6921 is widely used in industries where strength, corrosion resistance, lightweight, and non-magnetic properties are essential:

-

Nuclear Industry: Used in reactors, piping, and associated components where titanium and titanium alloys are required for corrosion resistance and durability.

-

Electronic Equipment: Ideal for mobile phones, computers, and other electronics due to being non-magnetic and lightweight, preventing interference with electromagnetic fields.

-

Medical Industry: Commonly used in clinical fracture fixation, orthopaedic implants, and medical devices due to biocompatibility, strength, and corrosion resistance.

-

Aerospace: Titanium bolts reduce aircraft weight while maintaining strength and elasticity, and are non-magnetic, preventing interference in sensitive aerospace systems.

-

General Industrial Use: Increasingly used beyond high-end precision industries, including automotive, marine, and specialised machinery applications.

Titanium hexagon flange bolts provide an irreplaceable combination of high performance, durability, and corrosion resistance, making them a preferred choice in demanding engineering and industrial applications.