-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

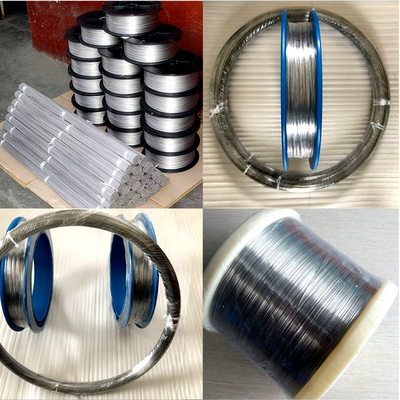

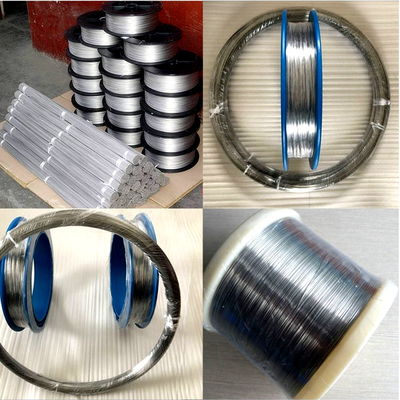

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Tungsten White Wire 0.1mm,0.2mm,0.3mm,0.5mm For Spring Filament Vacuum Electronic Device

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001;2015 |

| Model Number | W1 W2 |

| Minimum Order Quantity | 1kg |

| Price | USD98/kg |

| Packaging Details | film and wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,paypal |

| Supply Ability | 200kgs/month |

| Melting Point | 3410°c | Using | Spring Filament Vacuum Electronic Device |

|---|---|---|---|

| Material | 99.95% Tungsten Wire | Tensile Strength | 800-1000 MPa |

| Package | Wooden Boxes Package | Diameter | 0.1mm - 5.0mm |

| Surface | Polish/white | Superelasticity | Yes |

| Surface Finish | Polished | Corrosion Resistance | High |

| Length | Customizable | Elongation | 10-20% |

| Applications | Medical, Aerospace, Robotics | Biocompatibility | Excellent |

| Highlight | 0.1mm Tungsten White Wire,0.5mm Tungsten White Wire,0.3mm Tungsten White Wire |

||

Introduction

Tungsten stranded wire is a fine wire made of high-purity tungsten, known for its extremely high melting point, excellent electrical conductivity, and strong resistance to high temperatures.

It is widely used in applications that require stable performance under extreme thermal and electrical conditions.

Tungsten stranded wire can be classified into single-crystal and polycrystalline types:

Single-crystal tungsten wire is ideal for precision applications requiring high sharpness, such as electron sources in electron microscopes.

Polycrystalline tungsten wire is suitable for high-power applications such as electric heaters and lighting filaments.

Specification

| Product name | Tungsten stranded wire |

|---|---|

| Purity | 99.95% |

| Density | 19.3 g/cm³ |

| Melting point | 3410 °C |

| Boiling point | 5927 °C |

| Shape | Straight |

| Surface | Hot worked |

| MOQ | 2 kg |

| Applications | Filament, electrode, semiconductor heater components |

Applications

1. Electric Heating Devices

Tungsten stranded wire is commonly used as a heating element in electric furnaces, oven heating tubes, and industrial heaters.

Its high temperature resistance, mechanical strength, and corrosion resistance allow it to perform stably for long periods in extreme conditions.

2. Lighting Industry

Tungsten wire is one of the most important materials in the lighting field, especially in incandescent and halogen bulbs.

Its ability to withstand high temperatures enables it to emit stable light and maintain durability during extended use.

3. Vacuum and Electronic Devices

In vacuum technology, tungsten wire is widely used in electron tubes, vacuum furnaces, and semiconductor devices due to its low resistance, high evaporation temperature, and long lifespan.

4. Aerospace and Industrial Fields

Tungsten stranded wire is also applied in rocket engine nozzles, superalloy production, fiber processing, and high-temperature furnaces, where superior thermal and corrosion resistance are required.

Advantages

-

Excellent High-Temperature Resistance

– Melting point up to 3422 °C, suitable for extreme heat applications. -

High Strength

– Exceptional mechanical performance under high stress and pressure. -

Corrosion Resistance

– Resistant to oxidation, acids, and alkalis, maintaining long-term stability. -

Long Service Life

– Can operate stably in harsh environments for extended periods without degradation.