-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

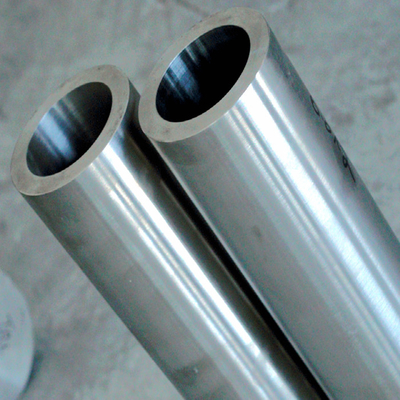

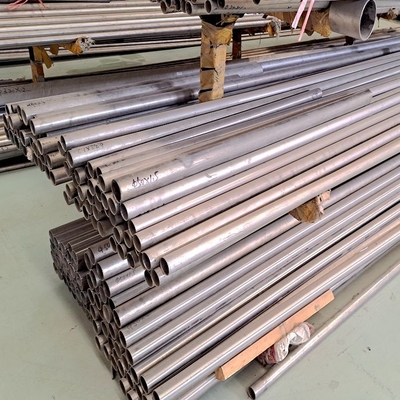

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Seamless Pipe Max length 9000mm in Stock For Condensers

| Place of Origin | CHINA |

|---|---|

| Brand Name | CHANGSHENG |

| Certification | ISO9000:2015 |

| Model Number | GR1 GR2 GR7 GR9 GR11 GR12 |

| Minimum Order Quantity | 10KG |

| Price | According to quantity |

| Packaging Details | Clients’ requirement |

| Delivery Time | 10 working days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 300 tons per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Shape | Round | Durability | Long-lasting |

|---|---|---|---|

| Corrosion Resistance | High | Applications | Aerospace, Medical, Chemical, Oil And Gas |

| Certifications | ISO 9001:2015 | Lead Time | 20 Work Days |

| Material | Titanium | Origin | Baoji City, China |

| Highlight | Condensers Titanium Seamless Pipe,9000mm Titanium Seamless Pipe |

||

Titanium Seamless Pipe Max length 9000mm in Stock For Condensers

size:12.7*0.9*L,22*0.9*L, 25*2*L.etc

length:9000mm max

MOQ:in stock

Product Introduction

The strength of titanium seamless pipes surpasses that of aluminum alloys, and their service temperature is significantly higher, being hundreds of degrees more than what aluminum alloys can withstand. Titanium seamless pipes maintain the required strength at medium temperatures and can operate for extended periods at temperatures ranging from 450 to 500 degrees Celsius. In contrast, the strength of aluminum alloys noticeably diminishes at temperatures starting from 150 degrees Celsius.

Titanium materials exhibit excellent corrosion resistance, particularly in humid atmospheres and seawater mediums, outperforming stainless steel in this regard. They are highly resistant to pitting, acid corrosion, stress corrosion, as well as alkali and chloride-induced corrosion. Additionally, they show outstanding corrosion resistance to nitric acid and sulfuric acid.

Titanium's low-temperature performance is exceptional, maintaining its mechanical properties even at low and ultra-low temperatures. With low thermal conductivity and a reduced elastic modulus, titanium tubes are predominantly used in heat delivery devices, condensers, separators, pipelines for seawater desalination, and pipe fittings for offshore oil drilling.

Quality control in the production of titanium pipes is stringent, encompassing a comprehensive process that ensures quality from the procurement of raw materials—including inspection of these materials—through pre-production preparations, the production phase, heat treatment, visual quality checks, inspections and testing, marking, packing and shipment, and finally certification.

|

Test equipment |

Ultrasonic flaw detector |

GS-22,CJS-22 |

2 |

|

X-ray flaw detector |

4X-2005,FX-2507C,XX-2505 |

3 |

|

|

Magnetic particle flaw detector |

CYE-3 |

1 |

|

|

Ultrasonic Thickness Gauge |

VSTm-500 |

1 |

|

|

Pressure testing machine |

SY350,DSY60 |

2 |

Specification

|

SEAMLESS TITANIUM PIPE |

||||||||||

|

S10 |

S40 |

S80 |

||||||||

|

Pipe Size |

OD |

Wall |

Inside Dia. |

lbs / ft |

Wall |

Inside Dia. |

lbs / ft |

Wall |

Inside Dia. |

lbs / ft |

|

1/8 |

.405 |

.049 |

.307 |

.1072 |

.068 |

.269 |

.1408 |

.095 |

.215 |

.1810 |

|

1/4 |

.540 |

.065 |

.410 |

.1897 |

.088 |

.364 |

.2442 |

.119 |

.302 |

.3079 |

|

3/8 |

.675 |

.065 |

.545 |

.2437 |

.091 |

.493 |

.3266 |

.126 |

.423 |

.4251 |

|

1/2 |

.840 |

.083 |

.674 |

.3861 |

.109 |

.622 |

.4896 |

.147 |

.546 |

.6260 |

|

3/4 |

1.050 |

.083 |

.884 |

.4932 |

.113 |

.824 |

.6506 |

.154 |

.742 |

.8479 |

|

1 |

1.315 |

.109 |

1.097 |

.8078 |

.133 |

1.049 |

.9660 |

.179 |

.957 |

1.2495 |

|

1-1/4 |

1.660 |

.109 |

1.442 |

1.0389 |

.140 |

1.380 |

1.3077 |

.191 |

1.278 |

1.7242 |

|

1-1/2 |

1.900 |

.109 |

1.681 |

1.1996 |

.145 |

1.610 |

1.5637 |

.200 |

1.500 |

2.0893 |

|

2 |

2.375 |

.109 |

2.157 |

1.5178 |

.154 |

2.067 |

2.1018 |

.218 |

1.939 |

2.8895 |

|

2-1/2 |

2.875 |

.120 |

2.635 |

2.0315 |

.203 |

2.469 |

3.3331 |

.276 |

2.323 |

4.4080 |

|

3 |

3.500 |

.120 |

3.260 |

2.4924 |

.216 |

3.068 |

4.3589 |

.300 |

2.900 |

5.8992 |

|

3-1/2 |

4.000 |

.120 |

3.760 |

2.8611 |

.226 |

3.548 |

5.2412 |

.318 |

3.364 |

7.1950 |

|

4 |

4.500 |

.120 |

4.260 |

3.2298 |

.237 |

4.026 |

6.2085 |

.337 |

3.826 |

8.6210 |

|

5 |

5.563 |

.134 |

5.295 |

4.4704 |

.258 |

5.047 |

8.4106 |

.375 |

4.813 |

11.9550 |

|

6 |

6.625 |

.134 |

6.357 |

5.3449 |

.280 |

6.065 |

10.917 |

.432 |

5.761 |

16.440 |

1. To ensure product quality, all of our products are manufactured in accordance with ASTM standards, and we perform a 100% inspection before shipping them out. In addition, we can provide the MTC Material Test Certification to guarantee the quality of our products.

2. we can print your logo on the products. We welcome customized orders and are committed to meeting your specific requirements.

3. We are happy to provide free samples for you to evaluate the quality of our products before making a purchase decision.

4. We accept various payment methods, including Telegraphic Transfer (T/T), Letter of Credit (L/C), PayPal, Western Union, Escrow, and MoneyGram, to accommodate different preferences and needs.

5. The necessary information for an inquiry includes the product name, specifications, material grade, standard, drawing, and the desired quantity. Providing these details will help us better understand your requirements and assist you effectively.

Welcome to enquiry!