-

Titanium Pipe Fittings

-

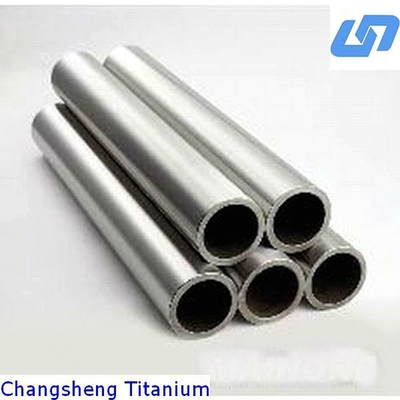

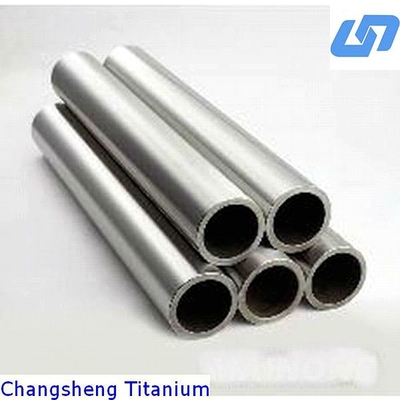

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

GR1 GR2 GR7 GR9 Titanium Welded Tube ASTM B337 For Heat Exchanger

| Place of Origin | CHINA |

|---|---|

| Brand Name | CHANGSHENG |

| Certification | ISO9000:2015 |

| Model Number | GR1 GR2 GR7 GR9 |

| Minimum Order Quantity | 100KGs |

| Price | According to quantity |

| Packaging Details | Clients’ requirement |

| Delivery Time | 10 working days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 300 tons per month |

| Application Fields | Aerospace, Medical, Marine | Size | Customizable |

|---|---|---|---|

| Supply Company | Baoji City Changsheng Titanium Co,. | Item | ASTM B337/338 Titanium Welded Tube |

| Surface Finish | Polished | Strength | High Strength-to-weight Ratio |

| Technique | Welded | Type | Seamless Titanium Pipe |

| Processing | Rolling Drawing Process | Length | Customizable |

| Highlight | GR7 Titanium Welded Tube,GR9 Titanium Welded Tube,GR1 Titanium Welded Tube |

||

GR1 GR2 GR7 GR9 Titanium Welded Tube ASTM B337 For Heat Exchanger

Standard:ASTM B337/B338

Material:gr1,gr2,gr7,gr9,Gr12

OD size:5mm above

Application: heat exchanger

Product Introduction

The initial investment cost for titanium welded tubes is indeed higher compared to conventional steel piping. However, the extended lifespan and reduced maintenance frequency of welded titanium tubes can offset the initial expenditure.

Utilizing Gr2 heat exchanger tubes in pipeline systems can decrease maintenance costs, increase productivity, and enhance profit margins. These tubes are predominantly fabricated into condensers and heat exchangers, finding application in sectors such as seawater desalination, petrochemical industries, and the power industry.

In highly corrosive environments, the use of welded titanium tubes is crucial to ensure equipment operates smoothly and to minimize both the time spent on maintenance and its frequency.

Specification

| Material | Manufacturing Process | Processing State | Diameter [mm] | Standards |

| Gr1, Gr2, Gr7, Gr11, Gr12, Gr17, nickel, niobium, molybdenum | Cold rolled | Cold rolled, annealed |

Φ3-273 L:9m(max) |

ASTM B337 ASTM B338 ASTM B861 |

| Gr1, Gr2, Gr7, Gr11, Gr12, Gr17, nickel, niobium, molybdenum | Welded | Annealed |

>Φ5 L:15m(max) |

ASTM B862

|

Titanium welded tubes are offered with common outer diameters (OD) including 16mm, 19.05mm, 22mm, 25.4mm, 32mm, and 38mm. The usual thicknesses range from 0.5mm to 1.5mm, in increments of 0.1mm, providing a selection of dimensions to cater to various applications.

In addition to the standard round tubes, custom square and rectangular shaped titanium tubes can be provided upon customers' request, allowing for specialized fitments where required.

Apart from titanium, we also supply nickel and nickel alloy welded pipes with diameters ranging from DN80 to DN1200, along with other special metals, offering a wide array of materials for different industrial needs.

Titanium welded tubes are frequently utilized in heat exchangers due to their high strength, superior corrosion resistance, and adequate thermal conductivity. The production of these tubes involves various welding techniques such as Tungsten Inert Gas (TIG) welding, plasma welding, and electron beam welding, ensuring robust and high-quality joins.

When selecting a titanium welded tube for use in heat exchangers, several factors must be considered to ensure compatibility and optimal performance. Key considerations include the tube's dimensions, thickness, and alloy composition, with Gr2 and Gr12 being the most commonly used titanium alloys for such applications.

The surface finish and cleanliness of the tubes are critical as they directly affect the efficiency of the heat exchanger. Contamination or defects in the weld can lead to reduced performance. Moreover, it is essential to assess the mechanical properties of the tubes, including their tensile strength, elongation, and hardness, to guarantee they meet the necessary specifications for the application.