-

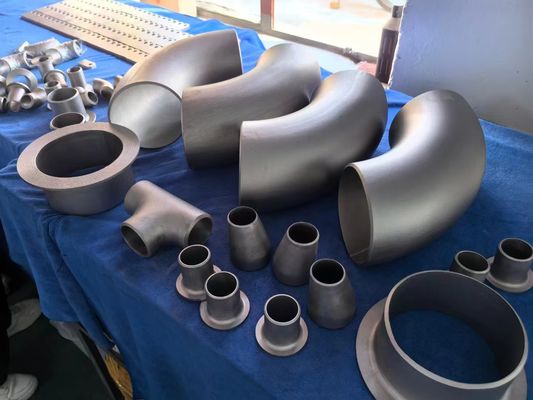

Titanium Pipe Fittings

-

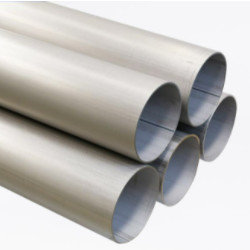

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Pipe Manufacturers China Aerospace Ocean Engineering

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001;2015 |

| Model Number | ASTM B 338 & ASME SB 338 |

| Minimum Order Quantity | 10kg |

| Price | USD16/pc |

| Packaging Details | Stardard export package |

| Delivery Time | 15-30days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,paypal |

| Supply Ability | 2000kgs/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Applications | Chemical Processing, Oil And Gas, Power Generation, Etc. | Rolling Process | Forging, Rolling, Annealing, Pickling |

|---|---|---|---|

| Degree | 45° 90° 180° | Connection Type | Butt Weld, Socket Weld, Threaded |

| Temperature Rating | Up To 600°F | Nps | 1 |

| Temperature Resistance | -60 To 540°C | Surface Finish | Polished, Sandblasted, Pickled |

| Biocompatibility | Certified For Medical Use | Materila | Pure Ttanium Or Alloy Titanium |

| Design Types | Customized | Connection | Welding,Seamless |

| Standard | ASTM B 338 & ASME SB 338 | Strength | High |

| Product Name | Titanium Pipe/tube | ||

| Highlight | Ocean Engineering Titanium Pipe,Manufacturers Titanium Pipe,China Aerospace Titanium Pipe |

||

Advantages

High resistance to corrosion

Non-magnetic properties

Low density and lightweight

Excellent heat transfer capability

High melting point

High tensile strength

Specifications

Seamless Pipe/Tube

Grade: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16, etc.

Outer Diameter: 3–110 mm

Wall Thickness: 0.1–5.5 mm

Length: ≤ 19,000 mm

Welded Pipe/Tube

Grade: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16, etc.

Outer Diameter: 10–1,000 mm

Wall Thickness: 0.5–5.5 mm

Length: ≤ 19,000 mm

Standards:

ASTM B338 / ASME SB338, ASTM B337 / ASME SB337, ASTM B861 / ASME SB861, ASTM B862 / ASME SB862, AMS 4911, AMS 4928

Material:

Gr1, Gr2, Gr5, Gr7, Gr9, Gr11, Gr12, etc.

Surface Treatment:

Pickled, polished, bright finish, etc.

Features

-

Low density and high strength

-

Excellent corrosion resistance

-

Good resistance to high temperatures

-

Excellent performance under cryogenic conditions

-

Non-magnetic and non-toxic

-

Good thermal conductivity

-

Low modulus of elasticity

Applications

Titanium has long proven to be an indispensable material across various industries due to its combination of strength, lightness, and corrosion resistance. It is widely used in:

Aerospace and aircraft manufacturing

Chemical processing plants

Oil and gas production

Power generation (e.g., surface condensers in power plants)

Marine environments

Titanium tubes and pipes can be easily fabricated, welded, and formed, making them suitable for many industrial operations.

There are currently 38 titanium grades recognised under ASME B338 and ASTM B338 standards. Common grades approved for pressurized service include Gr1, Gr2, Gr3, Gr7, Gr9, Gr11, Gr12, Gr16, Gr17, Gr26 (TIRU-26™), and Gr27 (TIRU-27™).

Among these, Grade 2 titanium is the most frequently used, particularly in power plant surface condensers.

Typical titanium alloy grades used for tubing include Ti-3Al-2.5V and Ti-6Al-4V.