-

Titanium Pipe Fittings

-

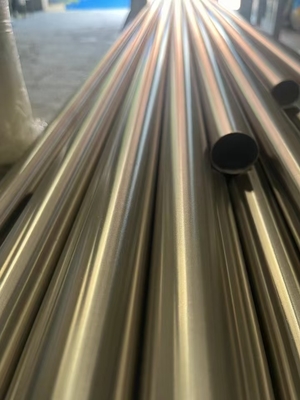

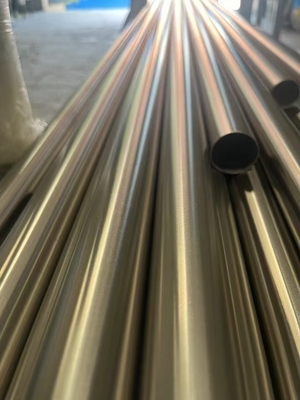

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

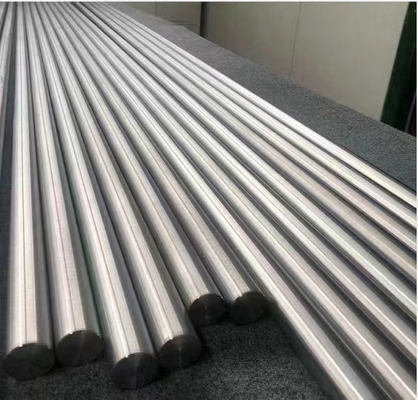

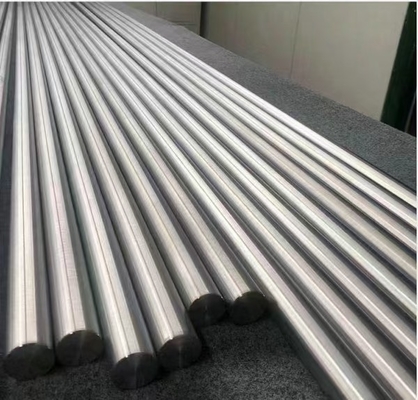

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Big OD Titanium Welded Tube Titanium Welded Pipe ASTM B862 Aerospace

| Materials | Titanium | Standard | ASTM B862 |

|---|---|---|---|

| Grade | Grade 1,Grade 2, Grade 7, Grade 12 | OD | 114-914mm; 5''-36'' |

| Wall Thickness | 2.77-31mm; SCH5S-SCH80 | Length | 1000-6000mm |

| Surface | Bright, Pickling, Polishing | Technical | Rolling, Welded,CNC |

| Highlight | Seamless Titanium Welded Tube,Titanium Welded Pipe ASTM B862,Bright Titanium Welded Tube |

||

Description

Big OD (large outer diameter) titanium welded tubes are manufactured from high-quality titanium metal and designed for applications requiring high strength, low weight, and exceptional corrosion resistance.

These tubes, produced to ASTM B862 standards, are widely used in medical, industrial, and aerospace fields where durability and performance are critical.

Compared with traditional steel or aluminium tubes, titanium welded tubes offer:

Superior corrosion resistance

Excellent mechanical strength

Lightweight design

High temperature and fatigue resistance

Titanium Gr1 welded tubes are commonly used in medical implants, while Ti Gr2 welded tubes are popular in industrial equipment such as heat exchangers, condensers, and chemical process systems.

Physical Properties

| Grade | Tensile Strength (MPa, Min) | Yield Strength (MPa, Min) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr3 | 450 | 380 | 18 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 / Gr5-ELI | 793 | 759 | 10 |

Chemical Composition

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al (%) | V (%) | Ni (max) | Mo (max) |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | – | – | – | – | – |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | – | – | – | – | – |

| Gr3 | 0.30 | 0.35 | 0.05 | 0.08 | 0.015 | – | – | – | – | – |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | – | – | – | – | – |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | – | 5.5–6.7 | 3.5–4.5 | – | – |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | – | – | – | – |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | – | 2.5–3.5 | 2.0–3.0 | – | – |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | – | 0.6–0.9 | 0.2–0.4 | – | – |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | – | 5.5–6.5 | 3.5–4.5 | – | – |

| Ti | Balance |

Advantages

-

High Strength & Lightweight: Combines excellent mechanical strength with low density for efficient performance.

-

Superior Corrosion Resistance: Performs well in seawater, chemical, and high-humidity environments.

-

High Temperature Resistance: Maintains stability and strength at elevated temperatures.

-

Excellent Weldability: Ti Gr2 welded tubes can be easily joined with other metals or components.

-

Fatigue Resistance: High fatigue limit makes them suitable for cyclic load conditions.

-

Biocompatibility: Safe for medical and biological use, including implants.

-

Aesthetic Appearance: Smooth metallic finish suitable for visible or decorative applications.

Applications

Big OD titanium welded tubes are used in a wide range of industries, including:

Aerospace: Airframe structures, exhaust ducts, and hydraulic systems

Automotive: Exhaust systems, suspension components, and heat exchangers

Medical: Surgical instruments, implants, and medical devices

Industrial: Chemical processing, condensers, evaporators, and pressure vessels

Marine: Seawater desalination, ship piping, and underwater components

Energy: Power generation and heat recovery systems

Standards

ASTM B862 – Welded Titanium and Titanium Alloy Tubes

ASTM B337 / B338 – Seamless and Welded Titanium Tubes

ASME SB-862 – Pressure Vessel and Heat Exchanger Applications

Available Grades

Titanium Gr1 – Best formability, moderate strength

Titanium Gr2 – Balanced corrosion resistance and weldability

Titanium Gr7 / Gr12 – Enhanced corrosion resistance for chemical industries

Packaging

All tubes are packed in strong wooden cases or bundles, protected with plastic film to prevent oxidation and mechanical damage during shipment.