-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

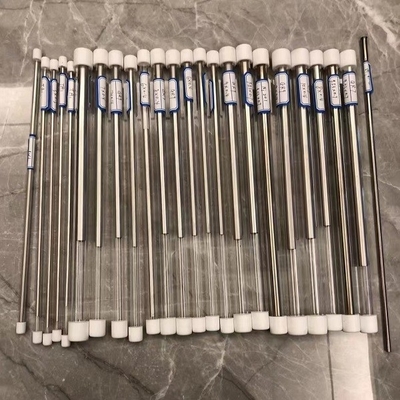

Titanium Ti-3Al-2.5V Capillary Tube Titanium Gr9 Seamless Tube For Medical And Marine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium | Grade | Ti-3Al-2.5V/UNS R56320/Grade 9 |

|---|---|---|---|

| OD | ≥3mm | Wall Thickness | >0.2mm |

| Roughness | 0.8um-1.6um | Tolerance | OD+-0.05mm;Wall Thickness:+-10% |

| Standard | ASTM B338 | Technique | Rolling, Pickling,Annealing,Polishing |

| Surface | Polished, Pickling | Application | Medical, Marine, Automobile And So On... |

| Highlight | Ti-3Al-2.5V Capillary Seamless Tube,Marine Seamless Titanium Tubing,Gr9 Titanium Medical Capillary Tube |

||

Description

Ti-3Al-2.5V (Titanium Grade 9, UNS R56320) is an alpha-beta titanium alloy containing aluminium and vanadium. It offers an excellent combination of strength, formability, and corrosion resistance. With a density of 4.43 g/cm³, a melting point of 1625–1675 °C, and a tensile strength of 900–950 MPa, this alloy is well-suited for demanding environments.

Titanium Grade 9 capillary tubing is commonly used in aerospace, medical, and industrial applications where a high strength-to-weight ratio, biocompatibility, and resistance to seawater and chloride corrosion are essential.

Physical Properties

| Grade | Tensile Strength (MPa, Min) | Yield Strength (MPa, Min) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr3 | 450 | 380 | 18 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 (Gr5 ELI) | 793 | 759 | 10 |

Chemical Composition

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al (%) | V (%) | Ni (max) | Mo (max) |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | – | – | – | – | – |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | – | – | – | – | – |

| Gr3 | 0.30 | 0.35 | 0.05 | 0.08 | 0.015 | – | – | – | – | – |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | – | – | – | – | – |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | – | 5.5–6.7 | 3.5–4.5 | – | – |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | – | – | – | – |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | – | 2.5–3.5 | 2.0–3.0 | – | – |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | – | 0.6–0.9 | 0.2–0.4 | – | – |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | – | 5.5–6.5 | 3.5–4.5 | – | – |

| Ti | Balance |

Applications

-

Aerospace – Used in aircraft frames, engine components, and fasteners due to high strength-to-weight ratio and corrosion resistance.

-

Military – Applied in armour, vehicles, and weapon systems for lightweight and corrosion resistance.

-

Automotive – Used in exhaust systems, engine parts, and performance components.

-

Medical – Suitable for implants and surgical tools owing to biocompatibility and non-toxicity.

-

Sporting Goods – Used in high-performance bicycles, golf clubs, and tennis rackets.

-

Marine – Ideal for seawater-exposed parts like propeller shafts, valves, and heat exchangers.

-

Oil & Gas – Employed in valves, pumps, and heat exchangers for its corrosion and fatigue resistance.

-

Electroplating Industry – Used as anodes/cathodes in plating processes (nickel, chrome, gold).

-

Chemical Industry – Used in chlorine, caustic soda, and pigment production due to its chemical inertness.

-

Jewellery – Lightweight, hypoallergenic, and corrosion-resistant for rings, bracelets, and accessories.