-

Titanium Pipe Fittings

-

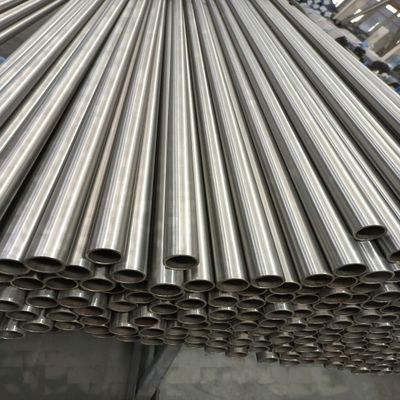

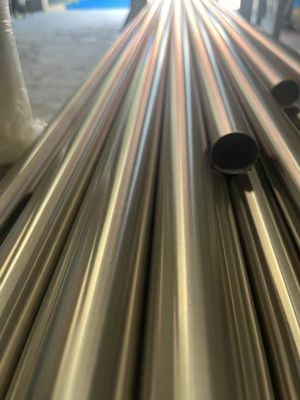

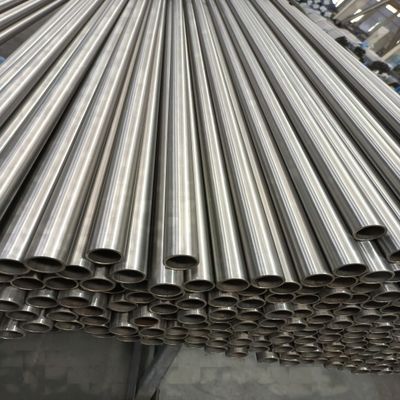

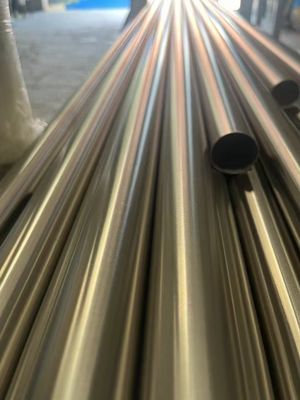

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Gr7 seamless tube Titanium Palladium Alloy Tube ASTM B861

| Materials | Titanium Target Alloy | Grade | Grade 7, UNS R52400 |

|---|---|---|---|

| Shape | Seamless Tube | OD | 15-914mm |

| Wall Thickness | SCH5S-SCH80 | Length | 1000mm-6000mm |

| Surface | Bright, Pickling | Standard | ASTM B338, ASTM B337, ASTM B861 |

| Highlight | Gr7 Titanium Palladium Alloy Tube,Seamless Titanium Alloy Tube,UNS R52400 Titanium Tubing |

||

Descriptions of Titanium Gr7 Seamless Tube (ASTM B861)

Titanium Grade 7 seamless tube (ASTM B861) is a corrosion-resistant titanium–palladium alloy known for its exceptional performance in highly oxidising or mildly reducing environments. Grade 7 is essentially commercially pure titanium (similar to Gr2) with 0.12–0.25% palladium added, which significantly enhances resistance to crevice corrosion, pitting, and stress corrosion cracking.

Titanium Gr7 seamless tubes provide an excellent combination of corrosion resistance, strength, fabricability, and weldability, making them suitable for demanding chemical, marine, and industrial applications.

Key Features

Excellent resistance to oxidising and reducing acids

Outstanding performance in chloride-containing environments

High resistance to crevice and pitting corrosion

Fully weldable and easy to fabricate

Suitable for high-purity chemical and pharmaceutical equipment

Corrosion Resistance of Titanium Gr7 Seamless Tube

Titanium Grade 7 exhibits exceptional corrosion resistance in a wide range of environments:

1. Neutral & Oxidising Media

Excellent resistance in neutral solutions, oxidising acids, and oxidising salts.

Highly resistant to wet chlorine gas, chlorite, hypochlorite, and chloride solutions.

2. Reducing Acids

Titanium Gr7 can be used in some dilute reducing acids, including:

Nitric acid with various concentrations

Mild sulfuric acid conditions

3. Alkaline Solutions

Highly resistant to saturated solutions of Ba(OH)₂, Ca(OH)₂, and Mg(OH)₂ at room temperature.

Not recommended for boiling sodium hydroxide due to potential corrosion.

4. Seawater & Marine Atmosphere

Completely resistant to corrosion in seawater.

Performs well in marine splash zones and subsea environments.

5. Organic Acids

Excellent resistance to most organic acids

Exception: Not suitable for formic acid or oxalic acid.

Mechanical Properties (ASTM B861 – Titanium Grade 7)

Tensile Strength (min): 348 MPa

Yield Strength (min): 275 MPa (max: 450 MPa)

Elongation (min): 20%

These properties provide a balanced combination of ductility and strength, similar to commercially pure titanium Grade 2 but with superior corrosion performance.

Chemical Composition of Titanium Grade 7 (ASTM B861)

(Typical Specification)

| Element | Content (wt%) |

|---|---|

| Palladium (Pd) | 0.12–0.25 |

| Nitrogen (N), max | 0.03 |

| Carbon (C), max | 0.08 |

| Hydrogen (H), max | 0.015 |

| Iron (Fe), max | 0.30 |

| Oxygen (O), max | 0.25 |

| Titanium (Ti) | Balance |

Applications of Titanium Gr7 Seamless Tube

Titanium Grade 7 tubes are widely used in environments requiring high corrosion resistance combined with moderate strength.

1. Aerospace Components

Compression members

Tubular struts

Fasteners and structural tubing

2. Marine Engineering

Propeller shafts

Heat exchanger tubes

Seawater cooling systems

Subsea structural components

3. Chemical Processing

Pumps

Valves

Heat exchangers

Reactors

Chlorine-handling equipment

4. Medical & Dental

Orthopaedic pins and screws

Dental implants

Surgical instruments

(Note: Grade 7 is less common than Grades 1, 2, or 23 but is still used in speciality applications)

5. Automotive

High-performance exhaust systems

Suspension components

Brake system hardware