-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

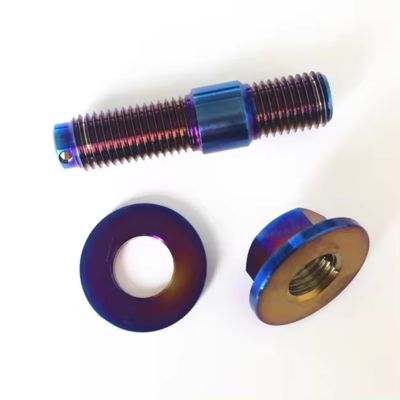

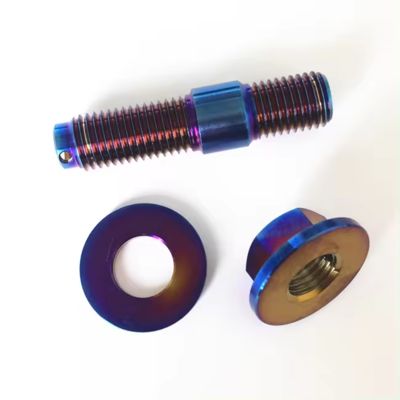

Titanium Wheel Bolt for Automobile Bicycle

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Dimensions | M1-M30 Or Customised | Surface Treatment | Polishing |

|---|---|---|---|

| Packing | 100pcs In Poly Bag | Powder Or Not | Not Powder |

| Grade | Grade 5 | Easy To Install | Easy To Install And Remove |

| Sample | Availabe | Equipment | CNC Machining Centres |

| Total Length | 46-63.05mm | Surface | Anodizing,Polishing |

| Temperature Resistance | Up To 600°C | Material | Titanium |

| Weight | About 2g/piece | Process | CNC Machining, Or Forged |

| Finish | Polished | ||

| Highlight | Gr5 Titanium Bolts,Automobile Bicycle Modification Titanium Bolts,Titanium Fasteners Wheel Screws |

||

Descriptions

Titanium Wheel Bolts are precision-engineered fasteners made from high-strength titanium alloys. They are commonly used in both automobiles and bicycles for their exceptional combination of lightweight, high strength, and excellent corrosion resistance.

Titanium wheel bolts are available through various automotive and cycling parts retailers, typically sold in sets. The required size depends on the specific application — common thread sizes include M5, M6, and M8.

Compared with conventional steel bolts, Titanium Grade 5 (Ti-6Al-4V) Wheel Screws provide significant advantages in weight reduction and durability, making them ideal for high-performance and outdoor environments. Although titanium bolts are more expensive, their long service life and superior performance make them a valuable investment for enthusiasts and professionals alike.

Grades of Titanium Wheel Bolt for Automobile and Bicycle

| Grade | Designation | Description |

|---|---|---|

| Gr1 | Pure Titanium | Excellent formability, corrosion resistance |

| Gr2 | R50400 | Commercially pure titanium with good strength and weldability |

| Gr5 | Ti-6Al-4V / R56400 | High strength, lightweight, most widely used titanium alloy |

| Gr7 | R52400 (Ti-0.2Pd) | Excellent corrosion resistance with added palladium |

| Gr23 | Ti-6Al-4V ELI / RS6401 | Extra low interstitial alloy, used in aerospace and medical applications |

Chemical Composition and Mechanical Properties

Mechanical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition (Weight %)

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al | V | Ni (max) | Mo (max) |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.2 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | — |

| Gr2 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | — |

| Gr4 | 0.5 | 0.4 | 0.05 | 0.08 | 0.015 | — | — | — | — | — |

| Gr5 (Ti-6Al-4V) | 0.4 | 0.2 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | — |

| Gr7 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | — |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | — |

| Gr12 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | — |

| Gr23 (ELI) | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | — |

Titanium (Ti): Balance

Customized Color Options

Titanium wheel bolts can be surface-treated through anodizing, offering a range of color options including:

Titanium natural, blue, gold, black, purple, and green, allowing both functional performance and aesthetic appeal for custom bikes and cars.

Applications of Titanium Wheel Bolt for Automobile and Bicycle

Automobile: Used for high-performance car wheels, suspension systems, and engine assemblies

Bicycle: Ideal for lightweight frames, hubs, cranksets, and brake rotors

Motorcycle: Commonly used for wheel assemblies and racing components

Marine and Outdoor Equipment: Perfect for corrosion-prone environments

Advantages of Titanium Wheel Bolt for Automobile and Bicycle

-

High Specific Strength

Titanium offers a density of 4.51 g/cm³ — lighter than steel but with far greater strength, ideal for reducing overall vehicle or bicycle weight. -

Excellent Corrosion Resistance

Titanium is resistant to corrosion in most environments, making these bolts suitable for coastal, marine, and outdoor use. -

Outstanding Temperature Performance

Operates reliably from –250°C to 600°C without deformation or loss of strength. -

Non-Magnetic and Biocompatible

Titanium bolts are non-magnetic, non-toxic, and biocompatible, making them safe for both industrial and medical uses. -

Strong Vibration Damping

Titanium exhibits superior vibration damping characteristics compared to steel or copper, enhancing ride comfort and performance stability.