-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Dia19mm X 0.5mm Titanium Tubes GR1 Seawater Condenser For Cooling

| Place of Origin | Shaanxi, China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO9001:2015 |

| Model Number | Seamless Titanium Tubes |

| Minimum Order Quantity | 5kg |

| Price | USD 19.0/KG - USD 28.0/KG |

| Packaging Details | Soft film wrapped inside, export standard crate outside. |

| Delivery Time | 3-5 work days |

| Payment Terms | L/C, T/T |

| Supply Ability | 30 Tons per Month |

| Material | Pure Titanium Grade 1 | Diameter | OD19mm |

|---|---|---|---|

| Wall Thickness | 0.5mm | Surface | Pickling Surface |

| Shape | Titanium Round Tube | Tubes Type | Seamless Tubes, Welded Tubes |

| Standard | ASTM B338 | Supply State | Anealed |

| Application | Heat Exchanger, Condenser, Evaporator, Chiller | Advantage | Good Welding Propertity, Ligh Weight, Corrosion Resistance |

| Lead Time | We Stock A Large And Varied Inventory, 3-5 Work Days | ||

| Highlight | 19mm X 0.5mm Titanium Tubes,Seawater Condenser Titanium Tubes,0.5mm Cooling Titanium Seamless Tube |

||

Dia19mm X 0.5mm Titanium Tubes GR1 Seawater Condenser For Cooling

Application: heat exchanger, condenser, evaporator, chiller, etc,.

Notes: Other dimensions will be supplied upon request.

Detailed Information in Form:

| Item name | Dia19mm X 0.5mm Titanium Tubes GR1 Seawater Condenser For Cooling |

| Cooling Media | Sea Water |

| Material | Pure Titanium Grade 1 |

| Type | Seamless tubes, and welded tubes |

| Standards | ASTM B338 |

| Shape | Round tubes with plain ends |

| Dimension | OD 19.0mm x Wall thickness 0.5mm x Length |

| Length | max.12m, or as per clients request |

| Surface | Pickling surface |

| Test | Eddy current inspection, Hydraulic test, Ultrasonic test |

Why choose titanium tubes?

- Under the same operating conditions, the wall thickness of titanium tube is thinner and the quantity of tubes are less. Generally, for copper alloy tubes and other material tubes, wall thickness is aound 0. 9 mm - 1. 2mm, while, by using titanium tubes, the tube wall thickness could be 0.5mm.

- Titanium tube has good thermal conductivity.The thermal conductivity of titanium is 17W/(m·k), Copper is 29W/(m·k). Titanium has the lowest thermal conductivity.

- The use of titanium tube is more cost-effective. The price of titanium tube can compete with that of copper alloy tube. Due to the low density of titanium and the same wall thickness, the mass of titanium tube of the same length is only 50% of that of copper alloy tube. When the wall thickness of titanium tube is 50% of that of copper alloy tube, the mass of titanium tube with the same heat transfer area is only 1/4 of that of copper alloy tube. Titanium tube is competitive in price.

- Titanium tubes have a longer service life. Because seawater is often mixed with sediment and marine organisms, they attach in the heat transfer pipe and pipe end, which will erode the copper alloy tube.

Marine Industry

Chemical and petrochemical industry

Pulp and paper industry

Medical industry

Nuclear industry

|

ASTM Grade

|

Alloy composition

|

Tensile strength

|

Yield strength

|

Elongation %

|

||

|

ksi

|

Mpa

|

ksi

|

Mpa

|

|||

|

GR1

|

Unallyed Ti(Pure)35A-CP1

|

35

|

240

|

25

|

170

|

24

|

|

GR2

|

Unallyed Ti(Pure)50A-CP2

|

50

|

345

|

40

|

275

|

20

|

|

GR5

|

Ti 6Al 4V

|

130

|

895

|

120

|

828

|

10E

|

| GR7 |

Ti-Pd

|

50

|

345

|

40

|

275

|

20

|

|

GR9

|

Ti 3AI 2.5V

|

90

|

620

|

70

|

483

|

15F

|

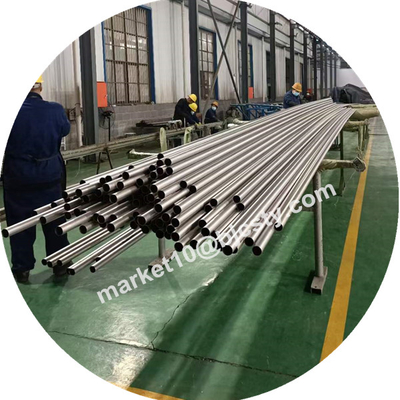

The first picture is pickling surface and seamless tubes. For heat exchanger tubings, the tube surface is usually pickling surface, the purpose of pickling is to remove the oxide skin produced after annealing of titanium tubes, a key process to ensure the quality of the tubes.