-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

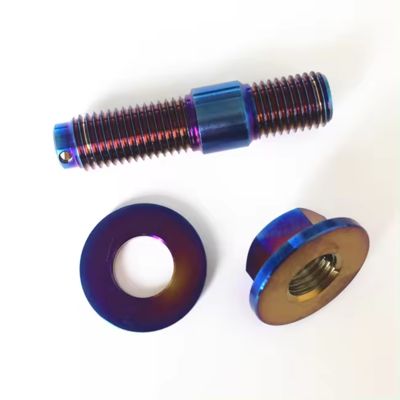

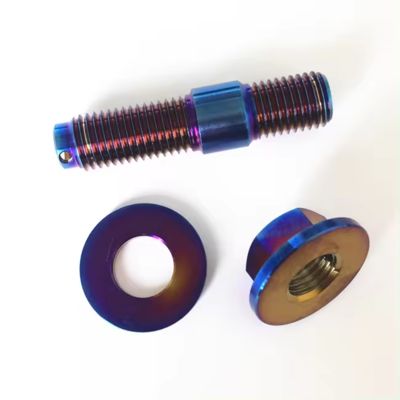

Titanium gr7 nut Titanium palladium alloy nut for bike and motorcycle

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium | Grade | Grade 1,Grade 5, Ti-6al-4v,grade 2,grade 4,grade 23,grade 7,grade 11 |

|---|---|---|---|

| Size | M3-M22 And Customized | Surface | Polished, Pickling,Anodizing |

| MOQ | 300PC | Color | Silver, Black,gold,purple,green.rainbow,blue |

| Technical | CNC,Stamping | Delivery Time | 7-10 Days |

| Highlight | Gr1 Titanium Fasteners,M30 titanium fasteners,Anodizing titanium motorcycle bolts |

||

Descriptions

Titanium Gr7 Nut is manufactured from a titanium-palladium alloy (Ti–0.15Pd) that offers exceptional corrosion resistance and superior mechanical strength. This alloy provides enhanced resistance to reducing acids and chloride-containing environments, making it ideal for demanding industrial applications.

Titanium Grade 7 nuts combine the lightweight and high-strength characteristics of titanium with the corrosion resistance benefits of palladium. They are widely used in chemical processing, marine, and aerospace industries, as well as in medical and industrial equipment where durability and ductility are critical.

These nuts also exhibit excellent weldability and high toughness, making them a reliable choice for use in chemical processing equipment, marine fastenings, and high-performance assemblies. With a maximum operating temperature of 600°F (316°C), Titanium Gr7 nuts perform well under both mechanical and thermal stress.

Available Specifications

-

Size: M2 – M60

-

Standards: DIN934, DIN935, DIN439, DIN557, DIN985, DIN6921, DIN6923, DIN6926, DIN1587, DIN6330

-

Head Styles:

-

Hex head nut

-

Flange nut

-

Nylon lock nut

-

Square nut

-

Slotted nut

-

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al (max) | V (max) | Others | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | Balance |

Advantages of the Titanium Gr7 Nut

-

Lightweight and High Strength: Ideal for applications requiring both low weight and high mechanical performance.

-

Outstanding Corrosion Resistance: Excellent performance in acidic, chloride, and marine environments.

-

Non-Magnetic and Non-Sparking: Safe for use in sensitive or explosive environments.

-

Biocompatible and Non-Toxic: Suitable for medical, food-processing, and pharmaceutical equipment.

-

Wear and Fatigue Resistance: Performs reliably under high dynamic loads and long-term use.

-

Excellent Machinability: Can be precisely manufactured to tight tolerances.

Applications:

Chemical processing equipment

Marine and offshore structures

Aerospace assemblies

Medical devices

Industrial fasteners