-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

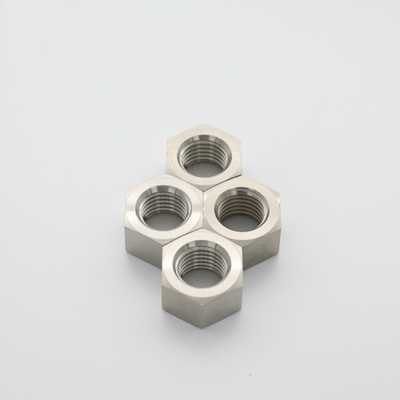

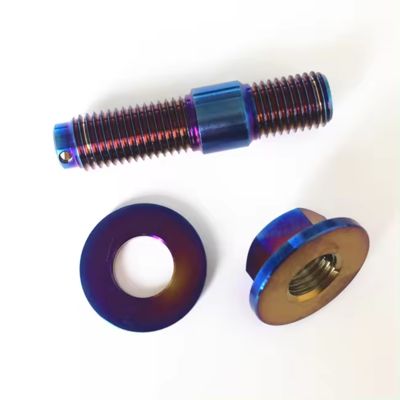

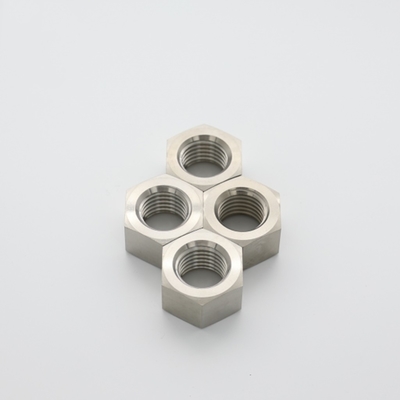

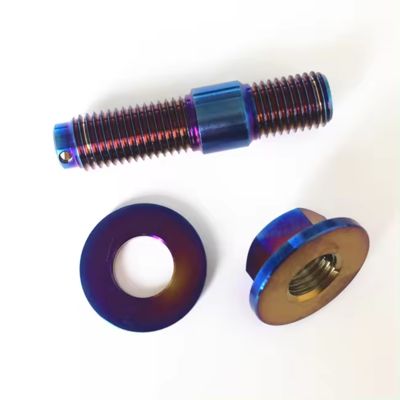

Din934 Titanium Hex nut for industry and bicycle

| Materials | Titanium | Grade | Grade 1,Grade 5, Ti-6al-4v,grade 2,grade 4,grade 23,grade 7,grade 11 |

|---|---|---|---|

| Size | M3-M22 And Customized | Surface | Polished, Pickling,Anodizing |

| MOQ | 100pc | Color | Silver, Black,gold,purple,green.rainbow,blue |

| Technical | Forge,welding | Delivery Time | 7-10 Days |

| Highlight | Ti6al4v Hex Socket Head Bolts,M4 Hex Socket Head Bolts,m8 titanium washer |

||

Descriptions of DIN934 Titanium Hex Nut

DIN934 Titanium Hex Nut is a precision fastener made from high-strength, lightweight titanium alloy, designed for use in applications requiring exceptional strength, corrosion resistance, and long-term durability.

It is widely applied in the aerospace, automotive, industrial, and marine industries due to its excellent mechanical and chemical stability.

DIN934 Titanium Hexagon Nut provides a strong and secure connection between two components. Its precise geometry ensures reliable tightening, while the external hex design allows easy installation using standard tools.

Titanium hex nuts are available in a range of sizes, pitches, and colours to meet various design and performance requirements.

Advantages of DIN934 Titanium Hex Nut

-

High Specific Strength

Titanium has a density of 4.51 g/cm³, which is lower than steel, copper, and nickel but much higher in strength. Titanium alloy nuts provide superior load-bearing capacity while reducing overall component weight. -

Excellent Corrosion Resistance

Titanium and its alloys are highly stable in many corrosive environments, including seawater, acids, and alkalis, making them ideal for marine and chemical applications. -

Wide Temperature Resistance

Titanium maintains excellent mechanical performance at temperatures up to 600°C and as low as -250°C, retaining its shape and integrity under extreme conditions. -

Non-Magnetic and Biocompatible

Titanium is non-magnetic and non-toxic, suitable for sensitive applications such as medical equipment and aerospace electronics. -

Superior Damping Properties

Titanium’s excellent vibration-damping capability allows it to be used in precision instruments, ultrasonic devices, and high-performance audio systems.

Specifications of DIN934 Titanium Hex Nut

Grade: Gr2, Gr5 (Ti-6Al-4V); UNS R50400 and UNS R56400

Size Range: M1 – M90 (custom sizes available)

Colour Options: Natural titanium, green, blue, gold, black, purple

Thread Pitch: 1.0 / 1.25 / 1.5 / 2.0 mm

Standard: DIN934

Physical Properties of DIN934 Titanium Hex Nut

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition of DIN934 Titanium Hex Nut

| Grade | Fe (Max %) | O (Max %) | N (Max %) | C (Max %) | H (Max %) | Pd (Max %) | Al (%) | V (%) | Ni (Max %) | Mo (Max %) |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | — |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | — |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | — |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | — |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | — |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | — |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | — |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | — |

| Ti | Balance |

Applications of DIN934 Titanium Hex Nut

DIN934 Titanium Hex Nuts are among the most widely used titanium fasteners across multiple industries. They are used to secure components together, especially in assemblies where weight reduction, corrosion resistance, and mechanical strength are critical.

Typical applications include:

Aerospace: Airframe structures, jet engines, and satellite systems

Automotive: Performance, racing, and lightweight vehicle components

Marine: Shipbuilding, offshore platforms, and seawater systems

Industrial: Chemical plants, heat exchangers, and machinery

Medical and Electronics: Non-magnetic and biocompatible system