-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

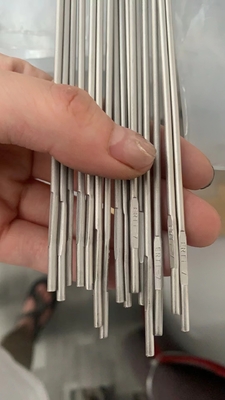

AWS A5.16 ERTi-1 ERTi-7 2.0mm 2.4mm 3.2mm Titanium Welding Wire For Biomedical

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | AWS A5.16 |

| Minimum Order Quantity | 10kgs |

| Price | $20.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 3-5days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 100000 pieces per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material Grade | Grade 1-5 (U.S.), Ti Gr1-Gr5 (Europe) | Rolling Process | Cold Rolling Straight |

|---|---|---|---|

| Wire Diameter | 2.0mm 2.4mm 3.2mm, Etc. | Materail | ERTI-1, ERTI-2,ERTI-5,ERTI-7 |

| Wire Surface | Bright Surface | Key Words | Titanium Flat Wire |

| Corrosion Resistance | Excellent | Condition | Coil And Straight |

| Electrical Conductivity | Moderate | Using | Fishing/glass/medical/industry |

| Technique | Cold Rolled Hot Rolled | Application | Welding, 3D Printing, Aerospace, Medical |

| Surface | Bright | Surface Finish | Polished, Oxidized |

| Package | Standard Export Package | ||

| Highlight | AWS A5.16 titanium welding wire,ERTi-1 biomedical welding wire,3.2mm titanium welding wire |

||

Introduction

Gr1 Titanium Welding Wire is a commercially pure titanium wire containing a minimum of 99% titanium. It is the softest and most ductile of all titanium grades, making it easy to form into various shapes and sizes.

This wire is typically produced through a cold drawing process, where a titanium rod is pulled through a series of dies to reduce its diameter while improving mechanical strength and surface finish.

Thanks to its excellent corrosion resistance and high-temperature stability, Gr1 titanium wire is widely used in the chemical industry, particularly for equipment that operates under harsh conditions involving high temperatures, pressure, and corrosive media.

Specification

| Item | Details |

|---|---|

| Product Name | Titanium Welding Wire |

| Grades Available | Gr1, Gr2, Gr5, Gr7, etc. |

| Standards | ASTM B348, ASTM SB348, ASTM B863 |

| Size Range | Diameter: 0.1 mm – 6 mm |

| Surface Finish | Pickled, Polished |

| Process | Cold Rolled / Cold Drawn |

| Applications | Aerospace, Chemical Equipment, Medical Devices |

Chemical Composition (Typical for Grade 1)

| Element | N | C | H | Fe | O | Al | V | Ti | Other (max) |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 0.03 | 0.08 | 0.015 | 0.18 | 0.20 | — | — | Balance | 0.4 |

Mechanical Properties

| Grade | Tensile Strength (min) | Yield Strength (0.2% offset) | Elongation (%) |

|---|---|---|---|

| KSI / MPa | KSI / MPa | ||

| Gr1 | 35 / 240 | 25 / — | — |

Applications

Chemical Equipment Fabrication

Used in the manufacturing of reactors, heaters, heat exchangers, storage tanks, and other components that operate under corrosive, high-temperature, and high-pressure conditions.

Equipment Connection and Repair

Essential for welding Gr2 titanium components, providing strong, corrosion-resistant joints in chemical and industrial systems.

Biomedical Devices

Increasingly used in orthopedic implants, dental prostheses, and cardiovascular components, due to its excellent biocompatibility, non-toxicity, and resistance to body fluids.