-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

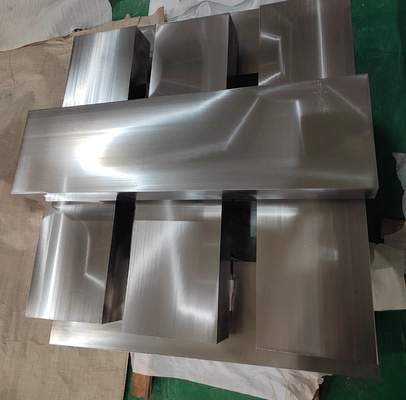

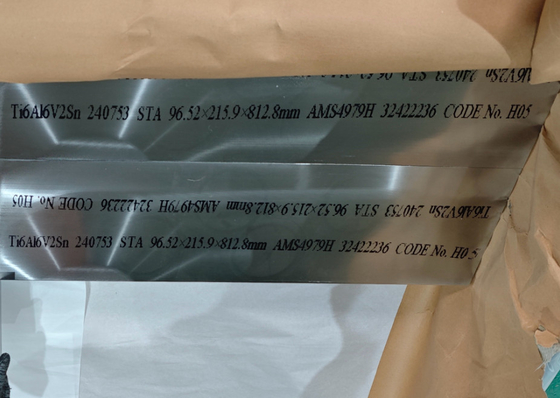

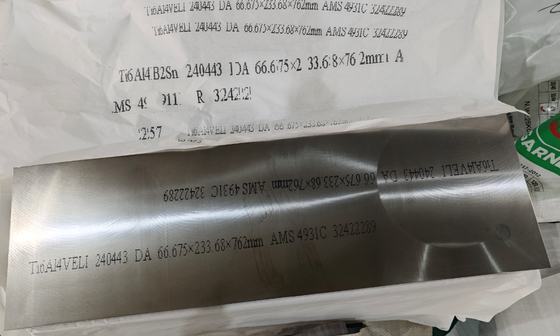

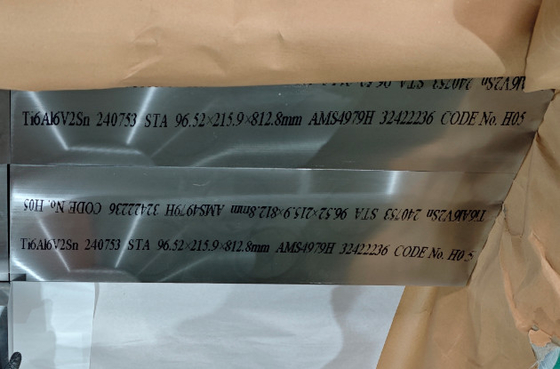

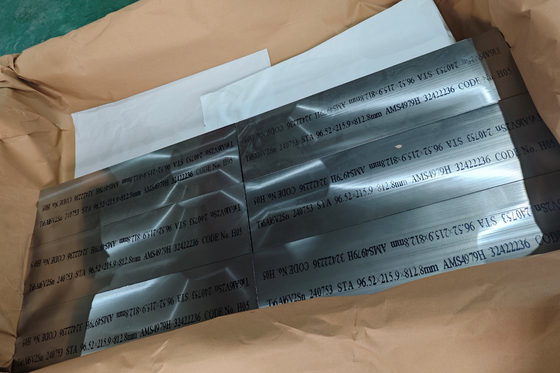

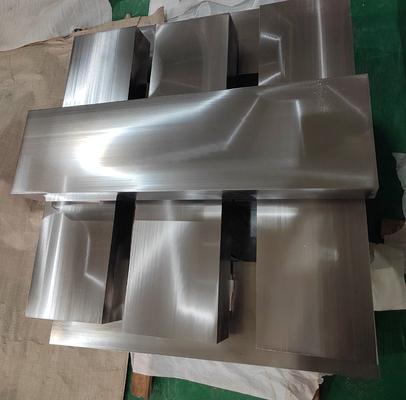

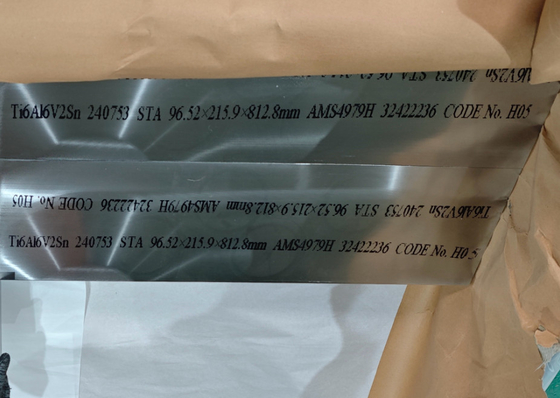

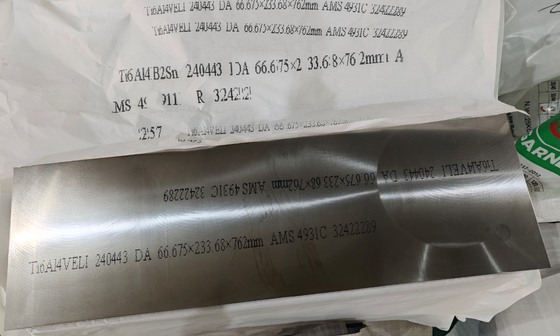

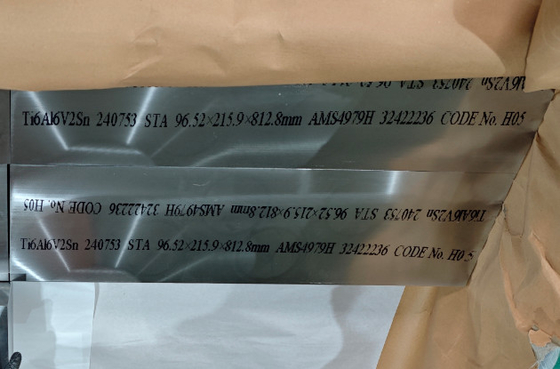

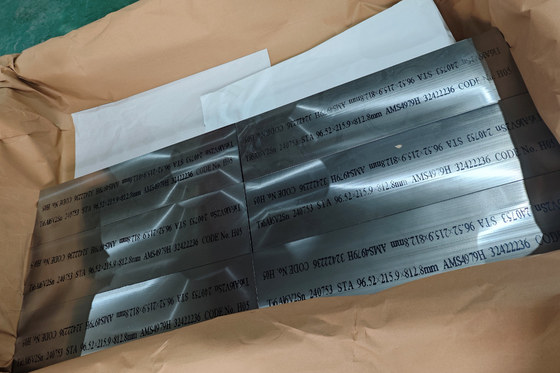

Customization Size Ti6AL6V2Sn Titanium Block AMS4979 H For Aerospace

| Length | Customized | Precision | High |

|---|---|---|---|

| Strength | High | Application | Aerospace, Medical, Military,High-End Machinery |

| Width | Customized | Grade | Ti6AL6V2Sn,Ti6AL4ELI |

| Material | Titanium | Durability | Long-lasting |

| Highlight | AMS4979 H Titanium Block,Aerospace Titanium Block Ti6AL6V2Sn,Customization Size Titanium Block |

||

Customization Size Ti6AL6V2Sn Titanium Block AMS4979 H For Aerospace

Ti6Al6V2Sn (AMS4979 H) is a high-strength titanium alloy widely used in aerospace, military, chemical, and high-temperature applications. It belongs to the α-β titanium alloy category and exhibits excellent comprehensive properties, including high strength, toughness, corrosion resistance, and thermal stability. The detailed analysis is as follows:

Chemical Composition

Ti6Al6V2Sn is composed of titanium (Ti), aluminum (Al), vanadium (V), and tin (Sn). The typical chemical composition includes:

- Titanium (Ti): Balance, providing the base strength and toughness of the alloy.

- Aluminum (Al): 6%, an α-stabilizing element that increases strength, hardness, and oxidation resistance.

- Vanadium (V): 6%, a β-stabilizing element that enhances ductility and high-temperature performance.

- Tin (Sn): 2%, another β-stabilizing element that improves thermal stability and corrosion resistance.

Properties and Characteristics

-

High Strength and Low Density

Ti6Al6V2Sn has excellent tensile and yield strength while maintaining a low density, making it ideal for weight-sensitive applications such as aerospace and military uses. -

Corrosion Resistance

Titanium and its alloys demonstrate exceptional corrosion resistance in various environments, including seawater and certain chemicals. Ti6Al6V2Sn specifically excels in such conditions. -

Outstanding High-Temperature Performance

This alloy withstands high working temperatures while maintaining its strength and stability, making it suitable for engine components and high-temperature environments. -

Excellent Weldability

Compared to other titanium alloys, Ti6Al6V2Sn offers good weldability, making it suitable for complex engineering structures.

Application Fields

Due to its high strength, thermal stability, and corrosion resistance, Ti6Al6V2Sn (AMS4979 H) is widely used in:

- Aerospace: Aircraft structural components, engine parts, turbine blades, etc.

- Military: Critical high-strength components for missiles, fighter jets, and other defense equipment.

- Chemical Industry: Corrosion-resistant equipment such as chemical reactors and petrochemical devices.

- High-End Machinery: High-load machinery, heat exchangers, and similar applications.

Processing and Heat Treatment

Ti6Al6V2Sn often undergoes rigorous heat treatments to enhance its mechanical properties. Common processes include:

- Solution Treatment: Heating the alloy to a specific temperature, holding it to dissolve elements into the solid solution, followed by rapid cooling.

- Aging Treatment: Controlled heating and holding to promote the precipitation of phases, thereby improving strength.

Summary

Ti6Al6V2Sn (AMS4979 H) is a versatile titanium alloy that excels in high-strength and high-temperature applications. Its excellent combination of strength, corrosion resistance, and thermal performance makes it indispensable in aerospace, military, and chemical industries.