-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

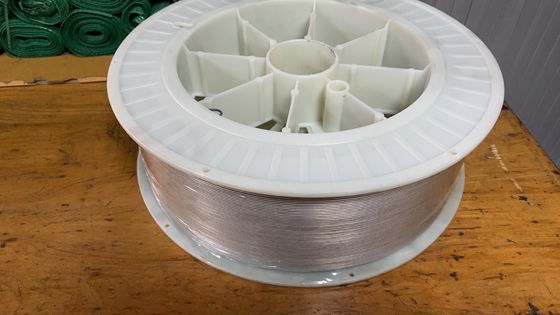

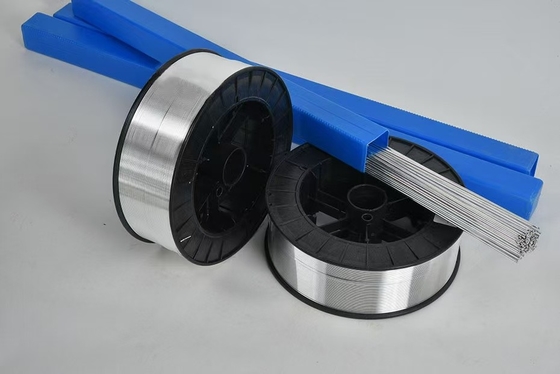

AWS A5.16 ERTi- Gr.1 2.4mm 3.2mm Titanium Welding Wire For Chemical

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | AWS A5.16 |

| Minimum Order Quantity | 10kgs |

| Price | $20.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 3-5days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 100000 pieces per Month |

| Melting Point | 1668°C | Tensile Strength | 700 MPa |

|---|---|---|---|

| Item | Titanium Welding Wire | Surface Color | Polished/black/blue/yellow/purple |

| Wire Surface | Bright Surface | Strength | 950 |

| Color | Silver, Black,pickling | Key Words | Titanium Welding Wire |

| Inventory | Large Stock | Width | 0.3-5mm |

| Technique | Cold Rolled Hot Rolled | Material Grade | Gr.1 Gr.2 Gr.7 |

| Feature | Shape Memory Superelastic | Available Forms | Straight, Coiled, Spooled |

| Supply Form | In Coil, On Spool, In Straight Lengths | ||

| Highlight | 3.2mm Titanium Welding Wire,Chemical Titanium Welding Wire,2.4mm Titanium Welding Wire |

||

Introduction

Gr1 titanium welding wire is a commercially pure titanium wire that contains a minimum of 99% titanium. It is the softest and most ductile among all titanium grades, making it easy to form into different shapes and sizes.

This pure titanium wire is typically produced through a cold drawing process, in which the titanium rod is pulled through a series of dies to reduce its diameter while improving its surface finish and mechanical strength.

Because of its excellent corrosion resistance and high-temperature stability, Gr1 titanium wire is widely used in the chemical industry, where it meets the demanding requirements of equipment exposed to aggressive environments.

Specification

| Product Name | Titanium Welding Wire |

|---|---|

| Grade | Gr1, Gr2, Gr3, Gr5, Gr7, Gr9, Gr12, Gr23 |

| Standard | ASTM B348, ASTM SB348, ASTM B863 |

| Size | Diameter 0.1 mm – 6 mm |

| Surface | Pickled, Polished |

| Technique | Rolled |

| Application | Aerospace, Chemical Equipment, Industrial Manufacturing |

Chemical Composition

| Grade | N | C | H | Fe | O | Al | V | Ti | Other (max) |

|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.03 | 0.08 | 0.015 | 0.18 | 0.20 | — | — | Balance | 0.4 |

Mechanical Properties

| Grade | Tensile Strength (min) | Yield Strength (0.2% offset) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 MPa (35 KSI) | 170 MPa (25 KSI) | 24% |

Applications

-

Chemical Equipment Manufacturing

Used in the production of reactors, heaters, heat exchangers, storage tanks, and other devices that operate under high temperature, high pressure, and corrosive conditions. Gr1 titanium wire’s superior corrosion resistance and temperature stability make it ideal for these environments. -

Equipment Connection and Maintenance

High-purity titanium welding wire is used for connecting and repairing titanium equipment, such as Gr2 titanium systems, ensuring strong and corrosion-resistant joints. -

Aerospace and Industrial Use

Applied in aerospace components and other industrial applications requiring lightweight materials with high strength and excellent corrosion resistance.

Key Features

Excellent corrosion resistance in oxidising and neutral environments

High ductility and formability

Outstanding weldability and purity

Stable mechanical performance at elevated temperatures

Suitable for high-demand chemical and aerospace environments