-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

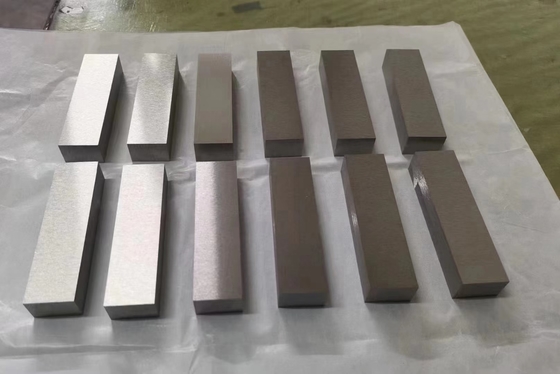

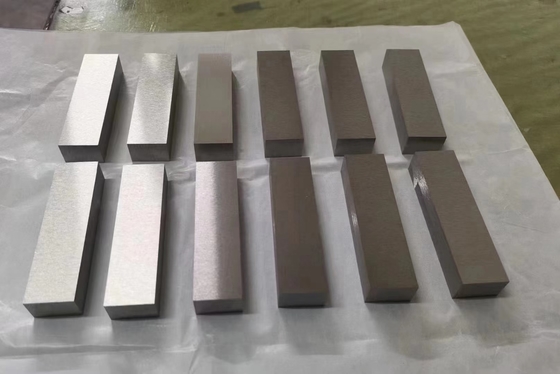

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Condition | Annealed | Elongation | 15% |

|---|---|---|---|

| Lead Time | 4-6 Weeks For Bulk Orders | Inner Diameter | 100-900mm |

| Ultrosonic Flaw Detection | A1 | Rolling Process | Hot-rolled, Cold-rolled |

| Weight | Lightweight | Uns | R50400, R56400, R52400 |

| Highlight | Annealed Alloy Steel Forgings,Ultrasonically Detected Flaw Alloy Steel Forgings,Inner Diameter Alloy Steel Forgings |

||

Product Description:

Features:

- Product Name: Titanium Forgings

- Width: 5-100mm

- Inner Diameter: 100-900mm

- Elongation: 15%

- Technology: Forging

- Lead Time: 4-6 Weeks For Bulk Orders

- Applications: Dental Titanium Disc, CNC Machining Titanium Parts

Technical Parameters:

| Inner Diameter | 100-900mm |

| Elongation | 15% |

| Surface Finish | Polished |

| Outer Diameter | 200-1300mm |

| Width | 5-100mm |

| Uns | R50400, R56400, R52400 |

| Powder Or Not | Not Powder |

| Strength | High |

| Rolling Process | Hot-rolled, Cold-rolled |

| Weight | Lightweight |

Applications:

The Titanium Forgings product is an excellent choice for 3D printing titanium alloy parts. The product's inner diameter and width specifications make it incredibly easy to work with in the printing process. Additionally, the lightweight nature of the product ensures that it does not become too heavy and cause printing issues. The polished surface finish of each forging is also an added benefit in 3D printing as it makes the parts look professional and high-quality.

Another application occasion for the Titanium Forgings product is in the production of enamel grade titanium dioxide. The product's lightweight nature makes it easy to work with, and the polished surface finish ensures that the titanium dioxide produced is of high-quality. The product's elongation of 15% is also an added benefit as it ensures that the titanium dioxide does not become brittle and crack during production.

The Titanium Forgings product is a popular material in the aerospace industry due to its lightweight nature. The product is used to create various parts and components for aircraft, including landing gear, engine parts, and structural components. The polished surface finish of each forging is also an added benefit in this industry as it ensures a high-quality appearance for each part. Additionally, the product's elongation of 15% is an added benefit as it ensures that the parts do not become too brittle and break during flight.

The medical industry also makes use of the Titanium Forgings product due to its lightweight nature and high-quality appearance. The product is used to create various medical devices, including implants, surgical tools, and equipment. The polished surface finish of each forging ensures that the medical devices produced are of high quality, while the product's elongation of 15% ensures that the devices do not become too brittle and break during use.

Customization:

Our Titanium Forgings product can be customized to meet your specific needs. We offer the following product customization services:

- Powder Or Not: Not Powder

- Elongation: 15%

- Lead Time: 4-6 Weeks For Bulk Orders

- Uns: R50400, R56400, R52400

- Strength: High

Whether you're looking for 3D printing titanium alloy, dental titanium disc, or aluminum forging parts, we can help you create the perfect product for your application. Contact us today to discuss your customization needs.

Support and Services:

Our Titanium Forgings product technical support and services include:

- Material selection guidance

- Machining recommendations

- Heat treatment advice

- Non-destructive testing

- Metallurgical analysis

- Failure analysis

- Custom designs and production