-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

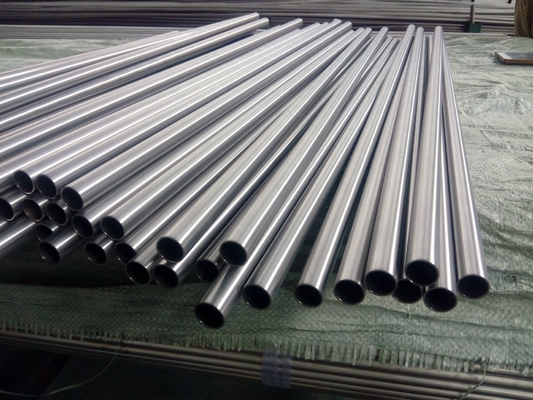

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

| Corrosion Resistance | High | Electrical Resistivity | 82.5 μΩ·cm |

|---|---|---|---|

| Memory Effect | Shape Memory | Using | Fishing/ Glass/ Medical/ Industry |

| Thermal Conductivity | 0.17 W/(m·K) | Density | 6.45 G/cm³ |

| Biocompatibility | Excellent | Superelasticity | High |

| Highlight | Corrosion Resistant Nitinol Wire,Fishing Applications Nitinol Wire,Medical Industrial Nitinol Wire |

||

Product Description:

One of the key features of this product is its high tensile strength, which makes it ideal for a range of applications. With a tensile strength that is significantly higher than other materials, the Shape Memory Nitinol Wire is the perfect choice for applications that require durability and strength.

Another important attribute of this wire is its electrical resistivity. With a resistivity of 82.5 μΩ·cm, it can be used in a range of electrical applications where conductivity is important.

The Shape Memory Nitinol Wire has a density of 6.45 G/cm³, which is relatively high compared to other materials. However, this high density is offset by its low elastic modulus, which makes it more flexible and easier to work with.

This wire is made using a specialized manufacturing process that involves a customized wire drawing machine and other advanced technologies. The result is a high-quality wire that is reliable and consistent.

One of the key applications of the Shape Memory Nitinol Wire is in the field of medicine. This wire is often used in surgical procedures as it can be easily manipulated and deformed to fit the needs of the surgeon. Additionally, its shape memory effect means that it can return to its original shape, which is useful in medical implants and other applications.

Other applications of this wire include its use in Black Annealed Rebar Wire, which is used in the construction industry. The Shape Memory Nitinol Wire is also used as a core material in Copper Clad Steel Wire, which is used in a range of electrical applications.

In summary, the Shape Memory Nitinol Wire is a highly innovative product that offers a unique set of attributes that make it ideal for a range of applications. Its high tensile strength, electrical resistivity, and low elastic modulus make it a reliable and flexible choice for a range of industries. Whether you need it for medical, construction, or electrical applications, this wire is the perfect choice for your needs.

Features:

- Product Name: Shape Memory Nitinol Wire

- Surface: Polish/black

- Elastic Modulus: Low

- Category: Shape Memory

- Biocompatibility: Excellent

- Using: Fishing/ Glass/ Medical/ Industry

- Copper Alloy Welding Wire: Not applicable

- High Temperature Alloy Wire: Not applicable

- Copper Clad Steel Wire: Not applicable

Technical Parameters:

| Electrical Resistivity | 82.5 μΩ·cm |

| Category | Shape Memory |

| Surface | Polish/black |

| Density | 6.45 G/cm³ |

| Surface Finish | Smooth |

| Superelasticity | High |

| Corrosion Resistance | High |

| Thermal Conductivity | 0.17 W/(m·K) |

| Material | Nitinol |

| Elastic Modulus | Low |

Applications:

The Shape Memory Nitinol Wire product is available in a polished or black surface finish, depending on the application requirements. The black surface finish is achieved through a process called black annealing, which also enhances the wire's corrosion resistance. This makes it suitable for use in harsh environments where corrosion is a concern.

One of the common applications of Shape Memory Nitinol Wire is in the construction industry, where it is used as black annealed rebar wire. This product is used as a binding wire for reinforcing steel bars in concrete structures. The black surface finish of the wire helps it blend in with the concrete, making it less visible and more aesthetically pleasing.

Another application of Shape Memory Nitinol Wire is in the medical industry, where it is used to make stents, orthodontic wires, and other implantable devices. The wire's shape memory effect is particularly useful in these applications because it allows the wire to return to its original shape after being deformed during the manufacturing process or during use.

Shape Memory Nitinol Wire is also used in the electrical industry, where it is used as a copper-nickel alloy wire. The wire's low electrical resistivity makes it an ideal material for electrical wiring, as it allows for efficient transmission of electricity.

In summary, Shape Memory Nitinol Wire is a versatile product that can be used in a variety of applications and scenarios. Its low elastic modulus, black surface finish, and shape memory effect make it an ideal material for use in construction, medical, and electrical industries.

Customization:

Our Shape Memory Nitinol Wire product comes with a range of customization services to suit your specific needs. Some of the customization options available include:

- Memory Effect: Shape Memory

- Using: Fishing/ Glass/ Medical/ Industry

- Surface Finish: Smooth

- Thermal Conductivity: 0.17 W/(m·K)

- Elastic Modulus: Low

If you require any other customization options, please don't hesitate to contact us. We are committed to providing you with high-quality products that meet your unique requirements.

Our Shape Memory Nitinol Wire is ideal for a variety of applications, including the production of Black Annealed Rebar Wire and Gabion Wire Mesh Machine. We also offer customization services for these applications.

Support and Services:

Our Shape Memory Nitinol Wire product comes with comprehensive technical support and services to ensure optimal performance and customer satisfaction. Our team of experts is available to answer any questions and provide guidance on product selection, installation, and use. We also offer custom fabrication services to meet specific design requirements.

In addition, we provide ongoing maintenance and repair services to extend the life of the product and minimize downtime. Our dedicated technical support team is committed to providing timely and effective solutions to any issues that may arise.

We value our customers and strive to exceed expectations in all aspects of our products and services. Contact us today to learn more about our Shape Memory Nitinol Wire and technical support offerings.