-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

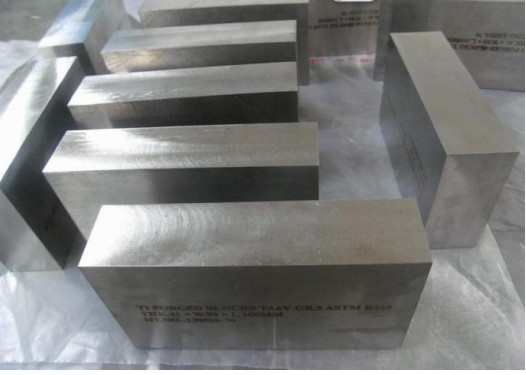

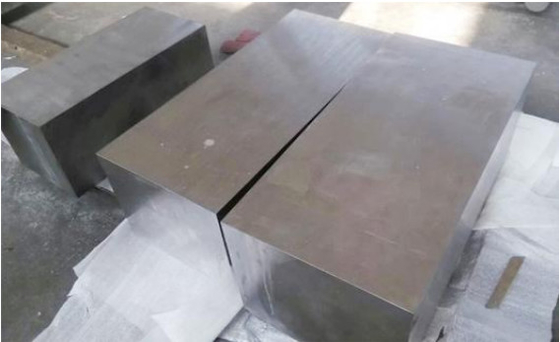

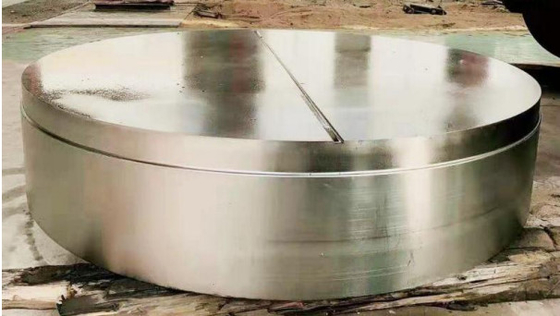

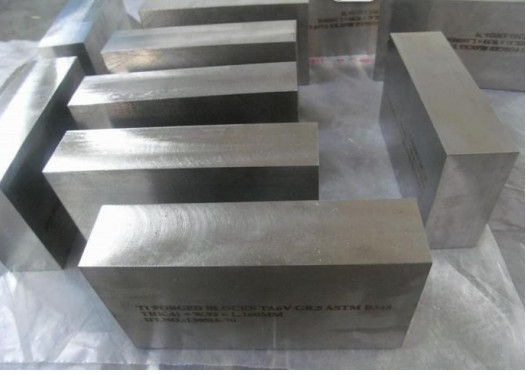

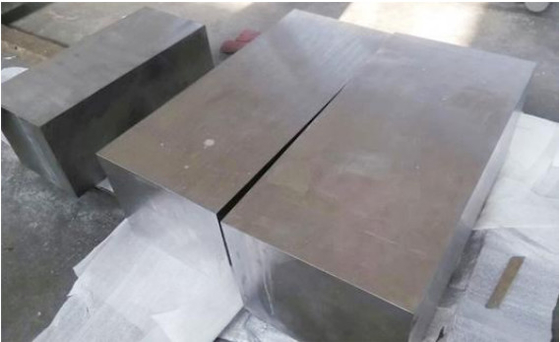

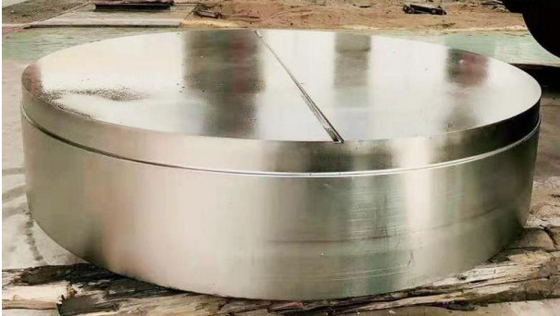

ASTM B348 Gr2 Gr5 Titanium Forged Block for Advanced Aeronautics and Chemical Applications

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | ASTM B348 |

| Minimum Order Quantity | 50kg |

| Price | $35.00 - $125.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Standard | ASTM B348,ASTM B381,AMS SB 4928 | Outer Diameter | 40-3000mm |

|---|---|---|---|

| Certifications | ISO 9001, AS9100 | Key Words | Forged Titanium Blcok |

| Powder Or Not | Not Powder | Applications | Aerospace, Medical, Automotive |

| Hardness | Typically 30-40 HRC | Technology | Forging |

| Dimension | D40-3000mm, Thickness 20-1000 Mm | Key Word | Titanium 6al4v Forged Blocks |

| Surface | Polished | Application | Chemical Industrial Or Aeronautics |

| Diameter | 3mm, 6mm, 300mmetc. | Heat Resistance | High |

| Condition | Annealed | ||

| Highlight | ASTM B348 Titanium Forged Block,Chemical Applications Titanium Forged Block,Aeronautics Titanium Forged Block |

||

Description

Titanium Gr2 Block is a solid block of commercially pure titanium with excellent corrosion resistance, strength, and low weight. It is one of the most commonly used titanium grades, offering an outstanding combination of formability, toughness, and weldability.

Titanium blocks are widely used in aerospace, automotive, marine, medical, and industrial applications where high performance, durability, and low density are required.

Each titanium block is milled or forged to precise dimensions and can be custom-machined to meet specific application requirements.

Available Grades

| Grade | UNS Number | Typical Use |

|---|---|---|

| Gr2 | R50400 | General-purpose applications, corrosion resistance |

| Gr5 (Ti-6Al-4V) | R56400 | High strength, aerospace, and medical uses |

| Gr7 | R52400 | Corrosion resistance with Pd addition for chemical industry |

Standards

ASTM B381 – Titanium and Titanium Alloy Forgings

ASTM B348 – Titanium and Titanium Alloy Bars and Billets

ASTM B265 – Titanium and Titanium Alloy Plates, Sheets, and Strips

GB/T 16598-1996, GB/T 25137-2013, GJB2744A-2007

Specifications

| Item | Specification |

|---|---|

| Product Name | Titanium Forged Block |

| Thickness | 10–600 mm |

| Width / OD | 80–1500 mm |

| Diameter Range | Φ40–3000 mm |

| Thickness Range | Φ20–1000 mm |

| Customization | Available upon request |

| Surface Finish | Polished, Machined, or Forged Surface |

| Processing Services | CNC Machining, Cutting, Drilling, Welding, Surface Treatment |

Testing & Quality Control

Titanium blocks undergo strict inspection and testing to ensure performance and integrity:

Chemical Composition Analysis

Mechanical Properties Testing

Hardness Testing

Metallographic Examination

Non-Destructive Testing (NDT): Ultrasonic Testing, Penetration Testing, Magnetic Particle Testing

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition

| Grade | Fe max (%) | O max (%) | N max (%) | C max (%) | H max (%) | Pd (%) | Al (%) | V (%) | Mo (%) | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | Balance |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | Balance |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | Balance |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | Balance |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | Balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | Balance |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | Balance |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | Balance |

Applications

-

Aerospace: Aircraft frames, engine components, landing gear, and structural parts.

-

Automotive: Exhaust systems, crankshafts, brake calipers, and lightweight chassis components.

-

Medical: Implants, surgical tools, dental components (especially Gr5 and Gr23).

-

Marine: Propeller shafts, hull reinforcements, and offshore equipment due to seawater resistance.

-

Industrial: Petrochemical processing, heat exchangers, and pressure vessels.

-

Military & Defense: Armor plating, missile casings, and structural support components.

Key Features

Excellent strength-to-weight ratio

Superior corrosion resistance in seawater and chemicals

Non-magnetic and biocompatible

Excellent weldability and machinability

Stable mechanical performance at elevated temperatures

Ordering Information

MOQ: Negotiable (samples available)

Lead Time: 10–15 working days

Packaging: Wooden crates or custom export packaging

Customization: Shapes, sizes, and surface finishes available upon request