-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

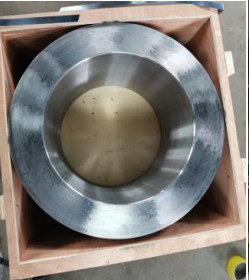

Titanium Forged Ring ASTM B348 Gr1 Gr2 Gr5 OD200~1100mm Hight 20-600mm

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | ASTM B348 |

| Minimum Order Quantity | 50kg |

| Price | $30.00 - $121.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Key Word | Titanium Forged Ring | Corrosion Resistance | Excellent |

|---|---|---|---|

| Wall Thickness | 50~200mm | Heat Treatment | Annealed |

| Height | H20mm-600mm | Dimension | OD:Φ700~1100 Mm ID:Φ300~900mm Section Height: 45~600mm |

| Technique | Hot Rolled | Size | Customized |

| Powder Or Not | Not Powder | Materials | Titanium And Titanium Alloy |

| Advantage | High Fatigue Resistance | Application | Aerospace |

| Surface Finish | Polished | Uns | R50400, R56400, R52400 |

| Highlight | Gr1 Gr2 Gr5 Titanium Forged Ring,OD200~1100mm Titanium Forged Ring,ASTM B348 Titanium Forged Ring |

||

Description

Titanium Forging Titanium Ring ASTM B381 is a high-performance titanium component produced through precision forging. These forged rings exhibit exceptional strength, corrosion resistance, and temperature stability, making them ideal for demanding applications in aerospace, chemical processing, energy systems, and medical industries.

The forging process enhances the mechanical properties of titanium, providing superior fatigue resistance and structural integrity compared to cast or machined components.

Specifications

| Product Name | Titanium Ring |

|---|---|

| Grade | National Standard: TA1, TA2, TA3, TA9, TA10, TC4, TC4ELI, TC6, TC9, TC11American Standard: GR1, GR2, GR3, GR4, GR5, GR7, GR11, GR12, GR23 |

| Standard | National: GB/T 16598-1996, GB/T 25137-2013, GJB 2744A-2007American: ASTM B348, ASTM B381, AMS 4928 |

| Dimension Range | - OD: Φ200–400 mm, ID: Φ100–300 mm, Height: 20–120 mm- OD: Φ400–700 mm, ID: Φ150–500 mm, Height: 35–600 mm- OD: Φ700–1100 mm, ID: Φ300–900 mm, Height: 45–600 mm |

| Processing Methods | Hot forging/machining |

| Testing Methods | - Chemical composition testing- Mechanical property testing- Hardness and metallographic analysis- Non-destructive testing: ultrasonic, penetrant, and magnetic particle inspection |

| Applications | Aerospace, aviation, military, light industry, chemical processing, medical, and petrochemical fields |

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr F-1 | 240 | 170 | 24 |

| Gr F-2 | 345 | 275 | 20 |

| Gr F-4 | 550 | 483 | 15 |

| Gr F-5 | 895 | 828 | 10 |

| Gr F-7 | 400 | 275 | 18 |

| Gr F-9 | 620 | 483 | 15 |

| Gr F-12 | 483 | 348 | 18 |

| Gr F-23 | 793 | 759 | 10 |

Chemical Composition (wt%)

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al | V | Ni (max) | Mo (max) | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gr F-1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | – | – | – | – | – | Balance |

| Gr F-2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | – | – | – | – | – | Balance |

| Gr F-4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | – | – | – | – | – | Balance |

| Gr F-5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | – | 5.5–6.7 | 3.5–4.5 | – | – | Balance |

| Gr F-7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | – | – | – | – | Balance |

| Gr F-9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | – | 2.5–3.5 | 2.0–3.0 | – | – | Balance |

| Gr F-12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | – | 0.6–0.9 | 0.2–0.4 | – | – | Balance |

| Gr F-23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | – | 5.5–6.5 | 3.5–4.5 | – | – | Balance |

Applications

Titanium Forging Rings (ASTM B381) are used across a wide range of high-performance industries:

Aerospace – airframe structures, engine components, and landing gear parts

Automotive – suspension systems, exhaust systems, and performance components

Chemical Processing – reactors, pressure vessels, and heat exchangers in corrosive environments

Energy & Power – turbines, generator components, and nuclear reactor systems

Industrial – valves, fasteners, and precision mechanical parts

Medical – orthopaedic implants, prosthetics, and surgical instruments