-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

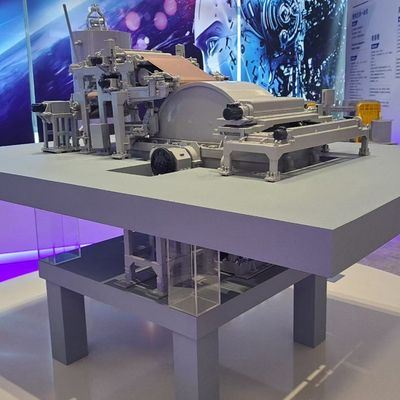

High Precision Offline Polishing And Grinding Machine For Cathode Drum

| Features | Adjustable Temperature, Non-Stick Coating, Removable Drip Tray | Material | Stainless Steel/Titanium |

|---|---|---|---|

| Accessories | Measuring Cup, Spatula, Recipe Book | Size | Medium |

| Certifications | ETL, FDA | Power Source | Electric |

| Highlight | Cathode drum polishing and grinding machine,Offline polishing and grinding machine,High precision polishing and grinding machine |

||

High quality Offline polishing and grinding machine for cathode drum

The offline polishing and grinding machine is super important in making electrolytic copper foil. It's used to polish and grind the cathode drum, which does a bunch of cool stuff:

1. **Smoother Surface**: It fixes all the dents and bumps on the drum's surface, making it nice and even. This helps keep the surface quality top-notch, ensuring the drum is steady and reliable during the electrolysis process.

2. **Better Precision**: The machine can really dial in the precision of the polishing and grinding, keeping the drum's diameter and width just right. This is key for making high-precision copper foil that meets what customers want.

3. **Lasts Longer**: Once the drum's been polished and ground, its surface is smoother, which means less friction with other equipment. This makes the drum last longer and cuts down on maintenance costs.

4. **Faster Production**: Using this machine for the cathode drum speeds up the polishing and grinding, which boosts how fast we can make stuff and ensures we meet our production schedules.

So, the offline polishing and grinding machine is a big deal for improving surface quality, getting that precision right, making things last longer, and speeding up production. It's an essential tool for making top-quality, efficient copper foil.

Below specification of the Offline polishing and grinding machine:

| Equipment | Specification |

| Polishing diameter of workpiece | 1500mm, 2016mm, 2700mm, 3000mm, 3600mm |

| Polishing width of workpiece | 1000mm to 1900mm |

| Maximum mass of workpiece | 10000kg |

| Workpiece speed | 0-25 rpm ( continuously variable ) |

| Main driving power | 7.5KW 4P |

| Speed of PVA grinding wheel | 0 -1000 rpm ( continuously variable ) |

| Motor power | 2.2KW (4P) |

| Size of PVA grinding wheel | ф300 x ф75 x 40mm ( customized according to customer's requiement ) |

| Coaxiality of grinding head | 0.005mm |

| Maximum Travel of the plate | 3000mm |

| Working speed of the plate | 5-1000mm/min (continuously variable ) |

| The precision of guide rail | 0.01mm - 0.015mm/M |

| Head of cooling pump | 2.5 m³ / min |

| Equipment control adopts | Japanese Mitsubishi, Lenze ULVAC ( REJ ) |