-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

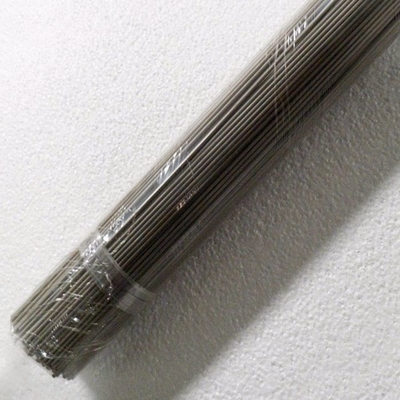

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Durable Titanium Welding Wire for Industrial Reactors Heaters and Heat Exchangers

| Supply State | Annealed | Keywords | 1.2mm Titanium ERTi-2 Welding Wire |

|---|---|---|---|

| Tensile Strength | ≥ 345MPa | Wire Gauge | 2.0mm |

| Surface Finish | Polished, Acid Washing | Titaniumsupply Form | In Coil, On Spool, In Straight Lengths |

| Technique | Cold Rolled Hot Rolled | Surface Color | Polished/black/blue/yellow/purple |

| Size | 0.03-6mm | Corrosion Resistance | Excellent |

| Diameter | 0.8mm-4.0mm | Tolerance | ±0.05mm |

| Item | GR7 Titanium Wire | Material Grade | Gr5 TC4 Ti 6Al 4V Ti64 |

| Condition | Coil And Straight | ||

| Highlight | Heaters Titanium Welding Wire,Heat Exchangers Titanium Welding Wire,Industrial Reactors Titanium Welding Wire |

||

Introduction

Gr1 titanium welding wire is a commercially pure titanium wire containing a minimum of 99% titanium. It is the softest and most ductile grade of titanium, making it easy to form into various shapes and sizes. Typically produced by a cold drawing process, the wire is pulled through a series of dies to achieve the desired diameter.

Thanks to its excellent corrosion resistance and high-temperature stability, Gr1 titanium wire is widely used in the chemical industry, where materials must perform reliably in demanding environments.

Specification

| Product Name | Titanium Welding Wire |

|---|---|

| Grade | Gr1, Gr2, Gr3, Gr5, Gr7, Gr9, Gr12, Gr23 |

| Standard | ASTM B348, ASTM SB348, ASTM B863 |

| Size | Diameter 0.1 mm – 6 mm |

| Surface Finish | Pickling, Polished |

| Technique | Rolled |

| Applications | Aerospace, Chemical Industry |

Chemical Composition (Max %)

| Grade | N | C | H | Fe | O | Al | V | Ti | Other (Max) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.03 | 0.08 | 0.015 | 0.18 | 0.20 | — | — | Balance | 0.4 |

Mechanical Properties

| Grade | Tensile Strength (min) | Yield Strength (0.2% offset) | Elongation (%) |

|---|---|---|---|

| 1 | 35 ksi (240 MPa) | 25 ksi (170 MPa) | 24 |

Applications

-

Chemical Equipment Manufacturing

Used in fabricating reactors, heaters, heat exchangers, and storage tanks that operate under high temperature, high pressure, and corrosive conditions. -

Welding and Maintenance

Applied in welding and repair of titanium equipment (especially Grade 2 titanium), requiring high-purity titanium filler wire for reliable joint performance.