-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

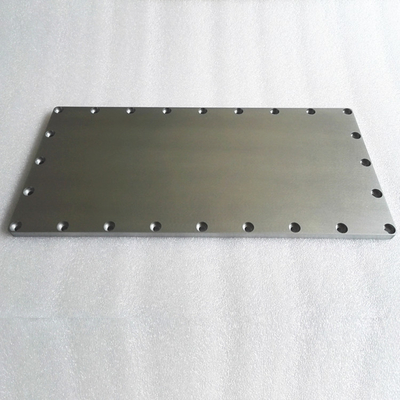

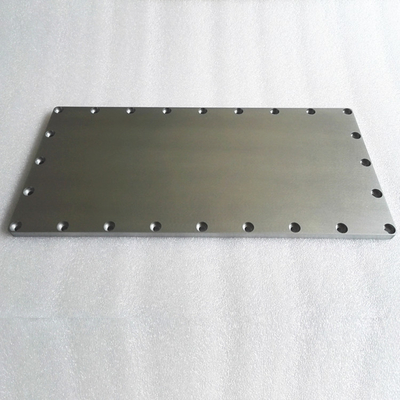

Customized Factory Price Titanium Targets 100*40mm 100*45mm,95*45mm Coating

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001;2015 |

| Model Number | ASTM B348 |

| Minimum Order Quantity | 200pcs |

| Price | USD24/pc |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,paypal |

| Supply Ability | 2000pcs/month |

| Grade | Grade 1, Grade 2 | Purity | 99.97% |

|---|---|---|---|

| Forming Process | Hot Isostatic Pressing(HIP) | Electrical Conductivity | Customized |

| Color | Metal Color | Melting Point | Customizable |

| Surface Roughness | Ra < 0.8 Um | Materials | Titanium |

| Composition | Customizable | Thermal Conductivity | Customized |

| Coating Method | Sputtering | Thickness | Customizable |

| Surface | Polished, Pickling, Anodizing | Size | Customizable |

| Substrate Compatibility | Customized | ||

| Highlight | Factory Price Customized titanium targets,Coating Titanium Targets |

||

Description

Sputtering targets are the source materials from which thin films are deposited using the sputtering process. These targets are fabricated from high-quality metals or ceramics through advanced melting, sintering, and machining techniques.

We offer a wide range of sputtering targets in various materials, purities, and geometries, including customized options. Depending on your application, the fabrication method can be optimised for best performance — ensuring ideal density, purity, and grain structure for thin film deposition.

Specification

| Item | Details |

|---|---|

| Product Name | Titanium Sputtering Target |

| Finish | Bright, Polished |

| Size | Customized |

| Material | Ti, Ti-Al, Zr, Cr, etc. |

| Available Shapes | Rectangle, Round, Rotary, Pellets, Ingots (as per customer’s requirement) |

| MOQ | 50 pcs |

| Technique | Customized OEM / ODM Service |

| Sample | Available |

| Features | Lightweight, Excellent Corrosion Resistance, High Mechanical Strength, Stable Performance |

| Testing Standards | 1. ISO 9001:2015 Certified2. Mechanical Property Testing3. Destructive and Non-destructive Testing per industry and customer requirements |

| Applications | Equipment components for aerospace, marine, automotive, medical, chemical, and sporting goods industries |

Applications

Titanium Targets

Titanium sputtering targets are widely used in hardware coating, decorative coating, semiconductor components, and flat panel display coating. Titanium is one of the key materials in integrated circuit production, where purities often exceed 99.99%.

Other Common Target Materials

Aluminium (Al): Used for semiconductor and heat-resistant coatings.

Copper (Cu): Ideal for electrodes and conductive coatings.

Tin (Sn): Enhances corrosion resistance.

Zinc (Zn): Provides protective coatings and serves as a corrosion barrier.

Precious Metals (Pt, Ag, Au): Offer chemical inertness and high electrical conductivity, suitable for high-precision electronic applications.

Key Features

High purity up to 99.995%

Excellent film adhesion and uniformity

Strong corrosion resistance and mechanical stability

Customizable shapes, sizes, and alloy compositions

Manufactured to meet ASTM and ISO standards

Typical Applications

Semiconductor and microelectronic devices

Optical coatings (beam splitters, anti-reflective layers)

Decorative coatings (watches, jewellery, consumer electronics)

Aerospace and automotive protective coatings

Biomedical surface modification (implants and instruments)