-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

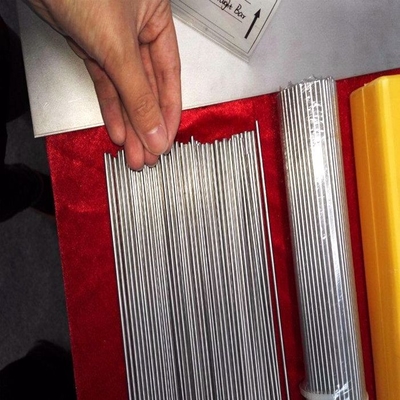

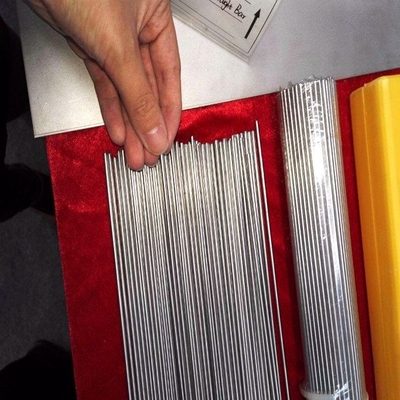

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

GR1 GR2 GR5 Titanium Welding Rod ISO TUV BV DNV for Aerospace

| Shape | Colied, Straight | Size | 0.03-6mm |

|---|---|---|---|

| Leading Time | 7-15days | Material Grade | Grade 1-5 (U.S.), Ti Gr1-Gr5 (Europe) |

| Application | Aerospace, Medical, Chemical Industry | Supply State | Annealed |

| Category | Shape Memory | Performance | Superelastic |

| Highlight | 3mm Titanium Clad Copper Wire,3mm Clad Copper Wire,Electroplating Field Clad Copper Wire |

||

GR1 GR2 GR5 Titanium Welding Rod ISO TUV BV DNV for Aerospace

Welding specification: AWS 5.16

Welded Wire: ERTil, ERTi2, ERTi3, ERTi4, ERTi5, ERTi7, ERTi9,ERTi12, ERTi23

Diameter (0.002" to 0.4") x Straight length/Spool/Coil

Diameter (0.05" to 10mm) x Straight length/Spool/Coil

Titanium welding rods are utilized in welding applications where titanium is required due to its superior strength, low density, and resistance to corrosion. These rods are commonly used in the Gas Tungsten Arc Welding (GTAW) process, also known as Tungsten Inert Gas (TIG) welding. This specification, developed by the American Welding Society (AWS), pertains to the use of titanium TIG welding rods. The AWS 5.16 specification outlines the requirements for classifying solid titanium welding electrodes and rods used in Gas Tungsten Arc Welding (GTAW) and Plasma Arc Welding (PAW) processes.

Titanium TIG welding wires are produced adhering to established national and international quality assurance standards, such as ISO, TUV, BV, DNV, GL, LLOYDS, and ISO.

Titanium filler rods are now available in a wide range of grades and diameters, from 1.0 mm to 3.2 mm in straight lengths, making the latest offering the most extensive range available online.

Titanium is twice as strong as steel, weighs half as much, and possesses extreme resistance to corrosion. ErTi-2 (Grade 2) TIG Welding Rod can be used to weld Grade 1, which represents the purest type of titanium.

The majority of titanium grades have excellent weldability; however, extra caution must be exercised to ensure that the weld pool is adequately protected by gas coverage. It is crucial that the weld pool remains shielded until it has cooled to at least 470 degrees Celsius.

Specification:

| Specifications and Standards for Titanium Wire/Welded Wire and its Alloys: | ||||

| Description | Grade | Size (English Units) | Size (Metric Units) | Standard |

| Wire | GR1, GR2,Gr5(Ti-6AL-4V), GR7, GR12, | Dia(0.0012〃・0・236〃)x St raightle ngth/Spool/Coil | Dia(0.03 - 6mm) x Straightlength/Spool/Coil | ASTM B863 |

| Welded Wire | ERTil, ERTi2, ERTi3, ERTi4, ERTi5, ERTi7, ERTi9,ERTil2, ERTi23, | Dia(0・002〃・0・4〃)x Straight length/Spool/Coil | Dia(0.05 ・ 10mm)x St raightlength/Spool/Coil | AWS A5.16 |

| According To The Different Production Process, The Titanium Wire Can Be Divided Into The Hot Drawing Titanium Wire And The Cold Titanium Wire. The Titanium Welding Wires We Supply Can Only Be Round Cross Section And Drawn From Titanium Wire Rods, They Are Made As Filler Metal For Welding Applications By Arc, MIG, TIG Procedures ・ | ||||

Common titanium alloys:

The following are common titanium alloys. When selecting a base titanium metal or titanium weld filler metal, there are many factors to consider to meet specific corrosion or mechanical properties. For material data on titanium electrodes, please contact our technicians directly for advice.

Filler materials used for welding-titanium alloys are described in the AWS 5.16 - Specification for Titanium and TIG Welding Titanium Filler Rod. The maximum useful temperature range for titanium structural applications is 800 to 1100 °F (427-593°C), depending on the selected alloy and its conditions. Unalloyed titanium is often chosen for its excellent corrosion resistance, especially in non-high strength applications. In addition to unalloyed or commercial titanium, different classes of titanium alloys are categorized by their microstructural phases: alpha, alpha-beta, and beta.

Finding a reliable supplier of titanium welding wire is essential. High-quality filler metals are crucial for producing good welds, particularly in critical applications such as aerospace and aircraft maintenance. Filler metals must be free from metallic and non-metallic impurities and have a clean, smooth surface without moisture, dirt, lubricants, or other contaminants. Proper storage and handling are also required to prevent poor soldering due to contamination. Baoji City Changsheng Titanium Co guarantees high-quality filler metal to customers, ensuring uniformity and freedom from surface defects and contamination.

We provide data and supply products in various re-sealable packaging bags that meet AMS, AWS, and other commercial practices, including vapor barrier envelopes with desiccants to keep the filler metal contained if stored in the original packaging.

Note: Commonly used titanium grades include commercially pure ASTM grade 2 (corrosion-resistant) with a strength of 350 - 450 MPa, and the higher strength Ti-6Al-4V alloy with a strength range of 900 - 1100 MPa.

Commercially pure titanium alloys are widely used due to their weldability, strength, corrosion resistance, and formability. ASTM grades 1 - 4 (alpha) are used primarily for their corrosion resistance, with each grade varying in impurity content; Grade 1 is the purest. Mechanical properties increase with grade level. Other alpha titanium grades like 7 - 11 - 16 - 17 contain palladium and offer excellent corrosion resistance, while grades 26 and 27 provide even higher corrosion resistance among many other options.

When welding CP alloys, typically, wire with a strength level one or two PSI lower than the base metal is used. Welds diluted with the base metal and micro-contamination will enhance the weld metal's strength. One significant advantage of welding commercially pure titanium grades is that they are over 99% pure, eliminating concerns about segregation. This applies to both commercial pure wire and electrodes.

Unalloyed grades account for roughly 30% of titanium production. They are generally weldable, and welded joints usually have acceptable strength and ductility. Post-weld stress relief annealing is recommended for weldments.

Application:

It provides a high-quality solution for welding titanium, widely used across industries where titanium's benefits are essential. The AWS 5.16 specification standardizes the production and testing of high-quality titanium welding rods, ensuring consistent quality and performance in welding applications. It is extensively used in the aerospace industry for welding components like engine parts, landing gears, and structural elements. Additionally, it serves marine applications requiring superior corrosion resistance against the corrosive effects of saltwater and other marine environments.