-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

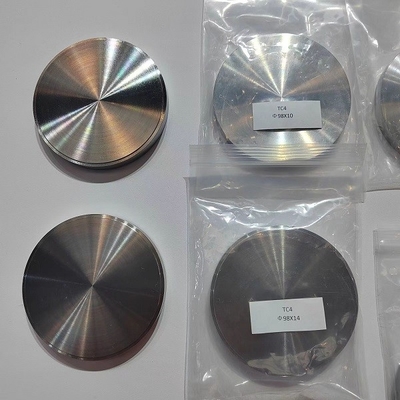

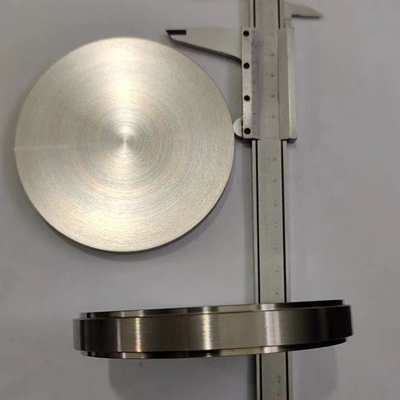

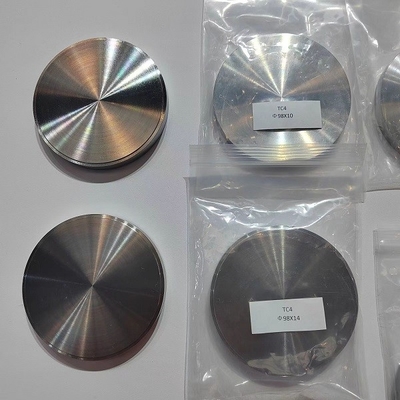

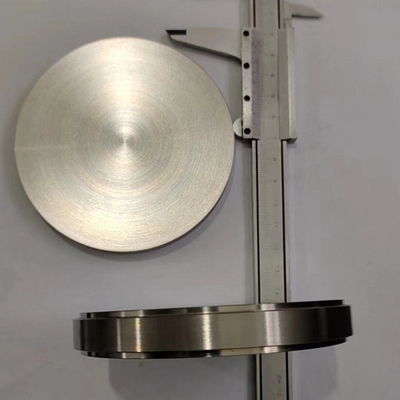

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Gr5-Eli Target Grade 23 Block For Dental Implant ASTM F136

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium | Grade | Grade 5, Grade 23 |

|---|---|---|---|

| OD | 90-600mm | Thickness | 1-100mm |

| Surface | Polished, Anodizing | Technical | Forge, Rolling, CNC |

| Density | Customized | Application | Thin Film Deposition |

| Composition | Customizable | Technique | Forged And CNC Machined |

| Forming Process | Hot Isostatic Pressing(HIP) | Target Backing | Copper, Aluminum, Titanium, Customized |

| Surface Finish | Customized | Target Bonding | Indium Bonding |

| Color | Metal Color | Crystal Structure | Customized |

| Target Type | Planar | Coating Method | Sputtering |

| Purity | 99.99% | ||

| Highlight | Gr23 Titanium Target Block,Dental Implant Titanium Target Block,ASTM F136 Target Block |

||

Description

Titanium Gr5-ELI Target, also known as Titanium Grade 23, is a titanium alloy composed of 6% aluminium, 4% vanadium, and extra low interstitial (ELI) elements.

It is derived from the standard Ti-6Al-4V alloy (Grade 5) but with tighter controls on oxygen, nitrogen, carbon, and iron content, providing superior toughness and fracture resistance.

Titanium Gr23 offers excellent corrosion resistance, high specific strength, and outstanding biocompatibility, making it the preferred titanium alloy for medical implants, aerospace structures, and high-performance engineering applications.

Chemical Composition (%)

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al | V | Ni (max) | Mo (max) | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.2 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr2 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr3 | 0.3 | 0.35 | 0.05 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr4 | 0.5 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr5 | 0.4 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | — | Balance |

| Gr7 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | — | Balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | — | Balance |

| Gr12 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | — | Balance |

| Gr5-ELI / Gr23 | 0.25 | 0.13 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | — | Balance |

Physical Properties

| Grade | Tensile Strength (MPa, min) | Yield Strength (MPa, min) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr3 | 450 | 380 | 18 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 / Gr5-ELI | 793 | 759 | 10 |

Applications

Titanium Grade 23 (Gr5-ELI) is one of the most commonly used titanium alloys for medical and aerospace applications due to its combination of strength, ductility, and biocompatibility.

Typical Applications Include:

Medical implants: bone screws, dental implants, joint replacements, and surgical instruments

Aerospace components: airframes, jet engines, and fuel systems

Marine and chemical equipment: corrosion-resistant structural components

Industrial parts: high-performance fasteners and high-strength precision blocks

Sputtering targets: thin-film coating, semiconductor, and optical industries

Key Features

Superior corrosion resistance in oxidising and reducing environments

High strength-to-weight ratio

Extra low interstitial content for improved toughness

Excellent biocompatibility for medical use

Good weldability and machinability