-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

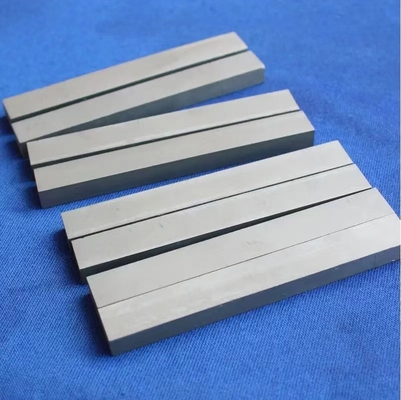

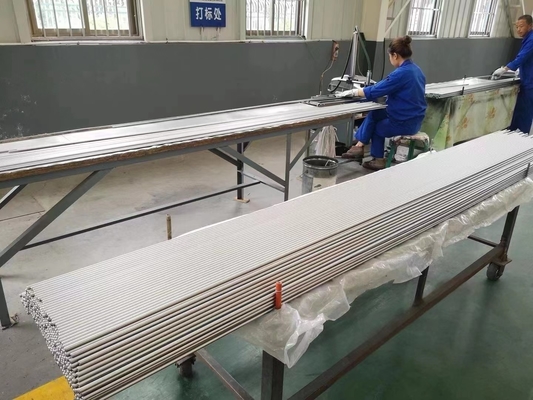

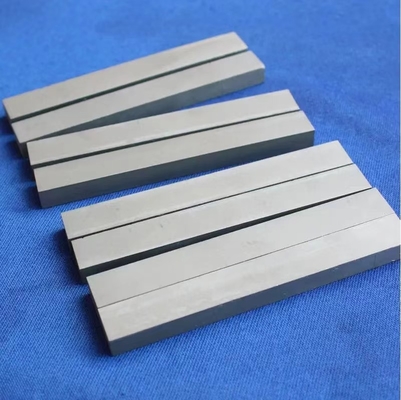

Titanium Square Bar Grade 2 Pickling Surface

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001;2015 |

| Model Number | ASTM |

| Minimum Order Quantity | 50kg |

| Price | 15usd/kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 10-15days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000T/MONTH |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Titanium | Grade | Grade 1,Grade 5,grade 2,grade 4,grade 23,grade 7,grade 11 |

|---|---|---|---|

| Length | 1000-6000mm | Surface | Bright, Pickling, Sandblasting |

| Thickness | 5-100mm | Width | 5-100mm |

| Heat Resistance | High | Surface Finish | Smooth |

| Keyword | Titanium Cnc Parts | Condition | Vacuum Annealed |

| Production Process | Hot Rolled/Annealed | Corrosion Resistance | Excellent |

| Materials | Titanium And Titanium Alloy | Tolerance | Tight |

| Machinability | Good | Strength | High |

| Melting Method | VAR Melting For 3 Times | Production Standards | ASTM B348, ISO 9001, AS9100 |

| Outer Diameter | 40-3000mm | Quality Control | Ultrasonic Testing |

| Highlight | Pickling Surface Titanium Square Bar,Gr2 Titanium Square Rod,5mm Aerospace Titanium Bar |

||

Description

Titanium Square Bar Grade 2 is a titanium alloy containing small amounts of elements such as aluminium and iron. It is lightweight, extremely strong, and highly corrosion-resistant, making it suitable for use in demanding environments.

Titanium square rods are available in a variety of grades, shapes, and sizes, and can be easily machined, welded, and formed. These properties make them ideal for aerospace, medical, automotive, and chemical processing applications.

Available Stock

Grades: Grade 2, Grade 5, Grade 7, Grade 12, Grade 23

Standards: ASTM B265, ASTM B348, ASTM B381

Surface Finish: Pickled, Polished

Width: 8–50 mm

Thickness: 8–50 mm

Length: 1000–6000 mm (customizable)

Applications

Titanium Square Bars are widely used in industries such as:

Architecture

Power Generation

Medical Industry

Hydrocarbon Processing

Marine Industry

Exhaust Pipe Shrouds

Airframe Structures and Skins

Desalination Plants

Chemical Processing

Chlorate Manufacturing

Mechanical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition (Typical Limits)

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al (max) | V (max) | Ni (max) | Mo (max) | Ti |

|------------|--------------|--------------|--------------|--------------|--------------|---------------|---------------|---------------|---------------|-------------|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | — | Balance |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | — | Balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | — | Balance |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | — | Balance |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | — | Balance |

Advantages

-

Outstanding Corrosion Resistance: Performs well in acidic, alkaline, and seawater environments.

-

High Strength-to-Weight Ratio: Ideal for aerospace, automotive, and biomedical applications.

-

Excellent Thermal Resistance: Grade 5 titanium can withstand high temperatures without deformation.

-

Non-Magnetic & Low Conductivity: Suitable for sensitive electronic applications.

-

Biocompatible: Non-toxic and safe for medical implants.

-

Easy Fabrication: Can be machined, welded, and formed into various shapes and dimensions.