-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

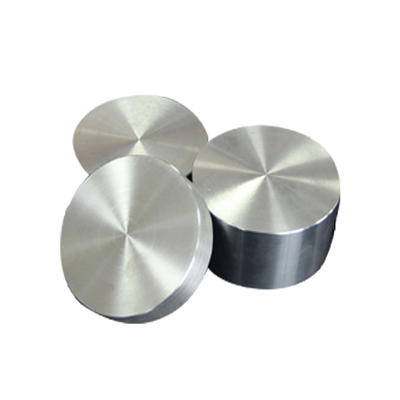

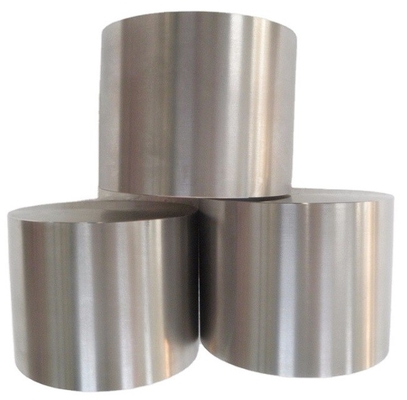

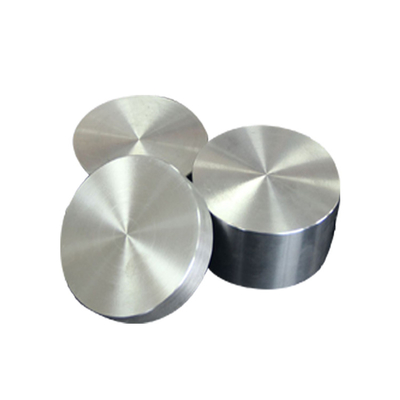

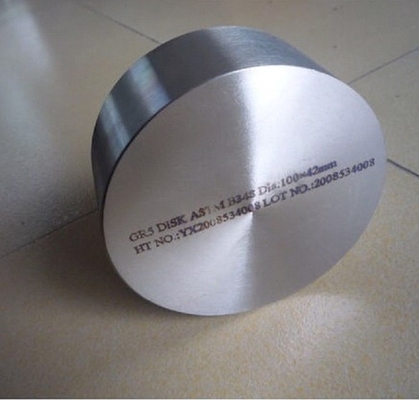

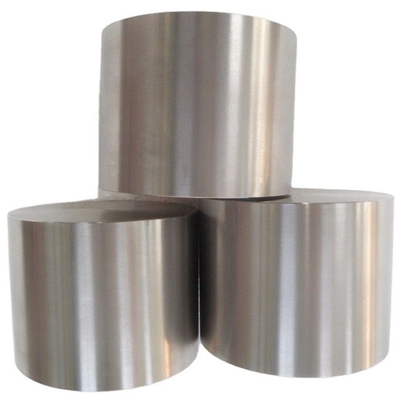

Titanium Gr2 Block Forging According To ASTM B381 Medical Aerospace

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001;2015 |

| Model Number | ASTM |

| Minimum Order Quantity | 50kg |

| Price | 15usd/kg |

| Packaging Details | film and wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 10-15days |

| Payment Terms | D/A, L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000T/MONTH |

| Materials | Titanium | Grade | Grade 2, Grade 5, Grade 7 |

|---|---|---|---|

| UNS | R50400, R56400, R52400 | Standard | ASTM B381, ASTM B348,ASTM B265 |

| Shape | Plate, Block, Disc | Thickness | 10-600mm |

| Surface | Bright, Pickling | OD/Width | 50mm-1500mm |

| Size | Customized Size Acceptable | Technical | Forged, Rolling, CNC |

| Highlight | Gr2 Titanium Blocks,10mm CNC Titanium Plate,Bright Forging Titanium Blocks |

||

Description

Titanium Gr2 Block is a solid block of titanium metal known for its exceptional strength, low weight, and excellent corrosion resistance. It is widely used across various industries such as aerospace, automotive, marine, and biomedical applications. Titanium blocks are typically milled and machined to meet specific design and performance requirements.

Specifications

| Item | Details |

|---|---|

| Grades Available | Grade 2, Grade 5, Grade 7 |

| UNS Numbers | R50400 (Gr2), R56400 (Gr5), R52400 (Gr7) |

| Standards | ASTM B381, ASTM B348, ASTM B265 |

| Thickness | 10 – 600 mm |

| Width / OD | 80 – 1500 mm |

| Length | Customised sizes available |

| Surface Finish | Pickled or Polished |

| Applications | Industrial, Aerospace, Oil & Gas, Automotive, Marine |

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition (Max%)

| Grade | Fe | O | N | C | H | Pd | Al | V | Ni | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | — |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | — |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | — |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | — |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | — |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | — |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | — |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | — |

| Ti | Balance |

Applications

-

Aerospace: Used in aircraft and spacecraft components such as frames, engines, and landing gear due to its high strength-to-weight ratio.

-

Automotive: Ideal for exhaust systems, brake components, and performance engine parts requiring lightweight and corrosion resistance.

-

Medical: Suitable for surgical implants, dental fixtures, and joint replacements thanks to its biocompatibility and durability.

-

Marine: Used for propeller shafts, hulls, and marine fasteners due to excellent resistance to seawater corrosion.

-

Industrial: Applied in chemical processing, desalination, and oil & gas equipment where high corrosion resistance is essential.

Key Advantages

Outstanding corrosion resistance in both oxidising and reducing environments.

Excellent strength-to-weight ratio and high-temperature performance.

Biocompatible and non-toxic, suitable for medical and food-grade applications.

Easy to machine, weld, and fabricate.

Excellent fatigue and crack resistance under cyclic loads.