-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

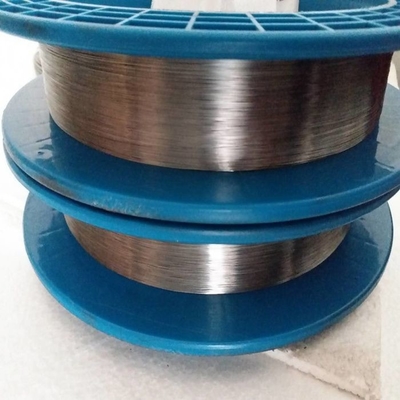

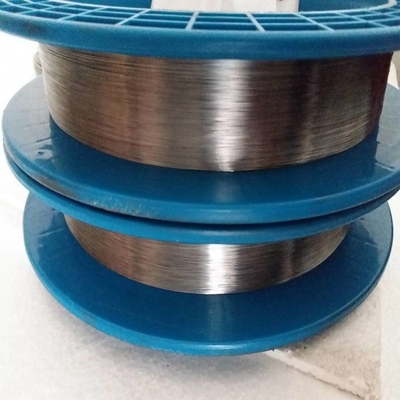

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Nitinol Flat Wire ASTM F2063

| Item | TC11 Titanium Alloy Welding Wire | Rolling Process | Cold Rolling |

|---|---|---|---|

| Inventory | Large Stock | Feature | Superelastic |

| Keywords | Solid Welding Wire | Applications | The Manufacture Of Surgical Implants |

| Category | Shape Memory | Supply Form | In Coil, On Spool, In Straight Lengths |

| Elongation | 20-30% | Diameter | 0.8mm-3.2mm |

| Package | Packed With Standard Export Wooden Case | Strength | 950 |

| Supply State | Annealed | Country Of Origin | China |

| Width | 0.3-5mm | ||

| Highlight | Super Elastic Memory Nitinol Flat Wire,Rectangle Nitinol Flat Wire,Alloy Titanium Welding Wire |

||

Descriptions

Nitinol Flat Wire ASTM F2063 is a precision-fabricated product made from nickel-titanium (NiTi) shape memory alloy. It is well known for its unique thermo-mechanical properties — shape memory effect (SME) and superelasticity (SE) — which distinguish it from conventional metallic materials.

The shape memory effect allows Nitinol to be deformed at one temperature and then recover its original shape when heated above its transformation temperature.

Superelasticity, on the other hand, occurs slightly above the transformation temperature, allowing the material to undergo large, reversible strains (up to 8%) without permanent deformation — 10 to 30 times higher than that of ordinary metals.

These exceptional mechanical and functional properties make Nitinol Flat Wire ASTM F2063 ideal for demanding applications in the medical, industrial, and consumer sectors.

Features and Advantages

-

Shape Memory Effect

Automatically returns to its original shape upon heating due to reversible phase transformation between austenite and martensite phases. -

High Superelasticity

Exhibits significantly higher elastic strain recovery than standard metals, providing superior flexibility and fatigue resistance. -

Excellent Fatigue Life

Demonstrates a fatigue life exceeding 10⁷ cycles, ensuring long-term durability even under cyclic stress. -

Good Corrosion Resistance

Offers excellent resistance to corrosion in various environments, especially in physiological and saline conditions. -

Superior Damping Properties

Provides vibration absorption 10 times better than ordinary metals, enhancing performance in dynamic environments. -

Stable Performance

Maintains consistent elasticity and transformation behaviour under varying thermal and mechanical conditions.

Available Sizes of Nitinol Flat Wire ASTM F2063

| Width × Thickness (mm) | Width Tolerance (mm) | Thickness Tolerance (mm) |

|---|---|---|

| 5 × 0.5 / 4 × 0.5 / 3 × 0.5 | ±0.10 | ±0.05 |

| 5 × 0.2 / 4 × 0.2 / 3 × 0.2 | ±0.08 | ±0.04 |

| 2 × 0.2 / 1.5 × 0.2 / 1.0 × 0.2 | ±0.05 | ±0.03 |

| 0.8 × 0.2 / 0.7 × 0.2 / 0.6 × 0.2 | ±0.02 | ±0.02 |

| 0.5 × 0.2 / 0.4 × 0.2 / 0.3 × 0.2 | ±0.02 | ±0.02 |

Applications of Nitinol Flat Wire ASTM F2063

Medical Devices: Stents, dental braces, orthodontic wires, surgical tools

Consumer Products: Eyeglass frames, fishing wire, springs

Industrial Uses: Actuators, couplings, and temperature control systems

Robotics and Automation: Shape-adaptive components that respond to heat or electrical stimuli

Construction Engineering: Vibration-damping and self-centring systems utilising Nitinol’s superelasticity

Understanding Nitinol Wire

Nitinol Wire is a functional alloy capable of recovering from plastic deformation upon heating to a specific temperature.

It has:

Expansion ratio: > 20%

Fatigue life: up to 10⁷ cycles

Damping capacity: ~10× that of standard steel

Corrosion resistance: superior to medical-grade stainless steel

Because of these properties, Nitinol is widely used in engineering, biomedical, and smart material applications as one of the most advanced metallic functional materials.

Advantages Summary

-

Excellent Shape Recovery: Returns to its original form via reversible thermal phase transformation.

-

Superior Elasticity: Exhibits recoverable strain far beyond conventional alloys.

-

Thermal Adaptability: Maintains strong elasticity even with temperature fluctuations — useful in construction and outdoor applications.

-

Outstanding Shock Absorption: Reduces vibration amplitude and structural stress during dynamic or seismic activity.

-

Wider Application Range than Steel: Combines strength, flexibility, and functional responsiveness, making it ideal for precision and smart technologies.

Nitinol Flat Wire ASTM F2063 combines mechanical strength with functional intelligence — making it an essential material in the next generation of high-performance, adaptive engineering and medical systems.