-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

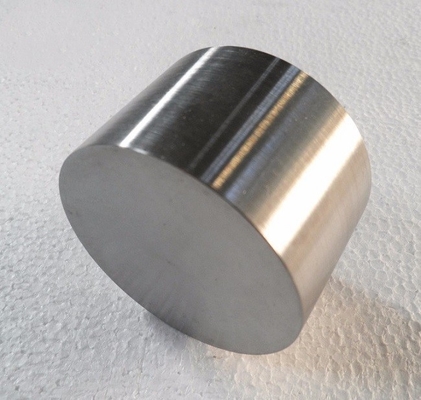

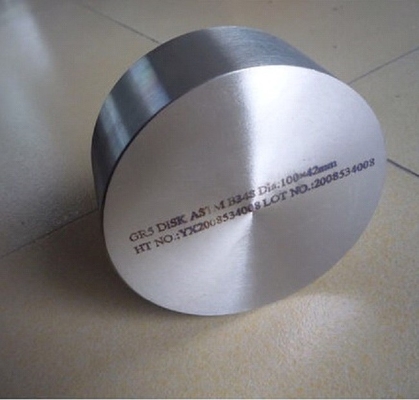

Die Hot Forging Gr9 Gr10 Titanium Forgings AMS 4928

| Place of Origin | China |

|---|---|

| Brand Name | CSTI |

| Certification | ISO9001 |

| Model Number | ASTM B381 Titanium Forged Blocks |

| Minimum Order Quantity | 5 Kilograms |

| Price | $15.80 - $25.50/ Kilogram |

| Packaging Details | wooden box or as your request. |

| Delivery Time | 15~25 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 30 Ton/Tons per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Titanium Forged Block | Material | Titanium Gr1gr2 Gr5 Gr9 Gr10 Gr12 |

|---|---|---|---|

| Shape | Round Disc Ring Square | Technique | Forging |

| Standard | ASTM B381 AMS4928 | Application | Petrochemical, Oil&Gas, Aerospace, Ship Building |

| Surface | Polishing Machined | Advantage | High Anti-corrosion Property, Excellent Bearing To Cryogenic Property |

| Highlight | AMS 4928 Titanium Forgings,Gr10 Titanium Forgings,Die Hot Forging titanium metal block |

||

1.Trustworthy China Titanium Forged Block Manufacturer Free Forging Die Forging Hot Forging

Item |

Description |

Product type |

Titanium Forged Parts |

Material |

Gr1,Gr2, Gr3, Gr4, Gr5, Gr5ELI,Gr7,Gr9,Gr12 |

Standard |

ASTM B348, ASME SB348,ASTM B381 |

Dimension |

OD20-1300mm ID60-900mm H40-250mm THK40-400mm |

Test |

Water pressure test, Ultrasonic test, X-ray test, Eddy current test, Flaring and Flattening test. |

Technology |

Forging/extruding/rolling/cold drawing |

State |

R or m |

Features |

Low Density and High Specification Strength

|

Packing |

Plywood case tied by steel band or as per client requirements |

|

MOQ

|

10KG

|

![]()

2. Changsheng Titanium supply titanium forging such as:

1) Titanium rings

2) Titanium discs

3) Titanium flanges

4) Titanium shafts

3. About the grade of titanium:

Grade1 can be used in the deep drawing parts for its good elogation and excellent corrossion-resistance.

Grade2 is widely used in the commercially pure Titanium.

Grade3 is almost only used in the pressure vessel.

Grade4 can be used in some fittings and fastening pieces,but for complete shape need 300 degree celsius to form.

Alloy Gr5 ,Ti6AL4V, is one of the most popular Ti alloys because of itscomprehensive mechanical, physical and chemical properties.

Alloy Gr7, add little palladium in cp Titanium and it has the most excellent corrosion-resistence.

Alloy Gr9, Ti3AL2.5v, is used mostly in the golf clubs and bicycle girders.

Alloy Gr11, it has the similar properties with the grade7.

4. Baoji City Changsheng Titanium Co.,Ltd

6. Application

welding flange

7. FAQ

1. Are you the manufacturing or trading company?

Real manufacturing company, started from 2001, nearly 20 years. With 2 sales teams for foreign trading business, started from 2008, more than 10 years experiences.

2. Do you have a dedicated R & D team? Can you design a product for us?

We have a dedicated technical team responsible for research and development. But most of titanium fittings are standard, we can follow ASTM or other you asked.

3. Can you provide samples? Is there a charge?

Samples can be provided for a fee.

4. What is your payment method?

We can accept T / T, LC, trade assurance order from alibaba.com. Samples are 100% prepaid. Orders for mass production are below 1000 USD, 100% prepaid, above 1000 USD, 30% prepaid, and 70% paid before delivery.

5. How long is your delivery time?

Inventory samples: within 3 working days Products for bulk orders: 25-30 days under normal circumstances.

6. After-sales products, how to deal with problems?

Based on our statistics for each year, the probability of problems with titanium products is around 0.8%. There are two main reasons for the problem:

1) Among the products that have problems, 93% are misplaced in pre-sales communication, and the product that the customer needs is not really clear.

2) 5% is an unexpected situation and the extension of the construction period.

3) 2% is the problem of transportation and packaging. During long-distance transportation, the packaging is damaged and the surface is damaged.

7. What is your company's response to the product in question?

1) Verify and blame for pre-sales communication issues. Compensation is handled according to the proportion of liability.

2) We are 100% responsible for problems caused by damaged packaging during transportation.

Tag:Titanium Alloy, Titanium Forged Disk, Titanium Forgings