-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

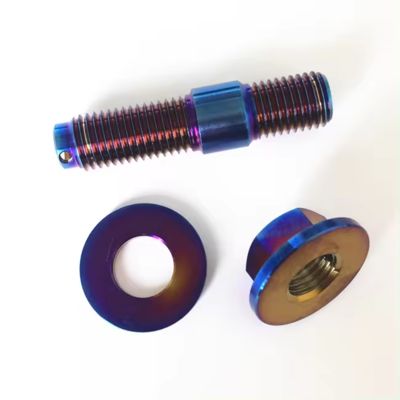

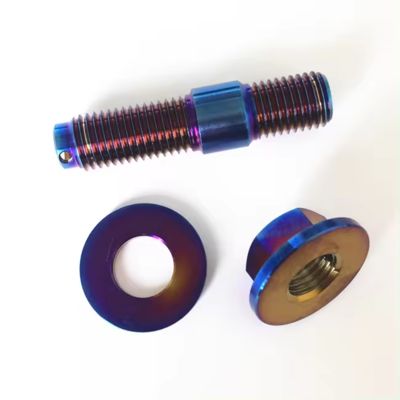

Customized Titanium Flange Nut with 6 points for Automobile Bicycle Modification

| Drive Type | Socket | Width | 6.5/8/9mm |

|---|---|---|---|

| Type | Screw | Custom Size | Workable |

| Versatile | Yes | Origin | Baoji, Shaanxi, China |

| Oem | Available | Dimensions | According To Your Requirement |

| Dimension | M3-M24 | Size | M8 |

| Thread Pitch | 1.25mm | Packing | 100pcs In Poly Bag |

| Item Name | Custom Titanium Parts | Technique | Cnc Machining,hot Rolled |

| Powder Or Not | Not Powder | ||

| Highlight | M3 Titanium Flange Hex Nuts,Gr5 Flange Hex Nuts,Ti6al4v titanium nut bolt |

||

Description of Titanium Flange Nut with 6 Points

Titanium Flange Nut with 6 Points is a high-performance fastener made from premium titanium alloy, designed for applications that demand exceptional strength, light weight, and corrosion resistance.

This type of nut integrates a hexagonal (6-point) head with a flanged base, which increases the contact surface area to ensure a secure connection and improved load distribution.

Titanium 6-Point Flange Nuts are widely used in the aerospace, automotive, marine, and industrial sectors due to their superior mechanical properties and reliability in harsh environments. They are available in various sizes, pitches, and colours to meet specific engineering needs.

Advantages of the Titanium Flange Nut with 6 Points

-

High Specific Strength

Titanium has a density of 4.51 g/cm³, lighter than steel but significantly stronger. Titanium flange nuts provide excellent mechanical strength while minimising overall weight, ideal for performance-critical applications. -

Outstanding Corrosion Resistance

Titanium and its alloys are stable in most chemical media, including seawater, acids, and alkalis, making these nuts perfect for marine and chemical processing environments. -

Excellent Heat and Low-Temperature Resistance

Titanium maintains its performance at temperatures up to 600°C and as low as −250°C, ensuring dimensional stability and reliability under extreme conditions. -

Non-Magnetic and Biocompatible

Titanium is non-magnetic, non-toxic, and highly compatible with the human body, suitable for sensitive environments such as medical, aerospace, and electronic applications. -

Superior Vibration Damping

Titanium exhibits excellent damping capacity, meaning it absorbs vibration more effectively than steel or copper. This makes it useful for high-precision instruments and vibration-sensitive systems.

Specifications of Titanium Flange Nut with 6 Points

Grade: Gr2, Gr5 (Ti-6Al-4V); UNS R50400 and UNS R56400

Size Range: M4 – M52 (custom sizes available)

Thread Pitch: 1.0 / 1.25 / 1.5 / 2.0 mm

Colour Options: Titanium natural, green, blue, gold, black, purple

Related Standards: DIN6926, DIN6923

Physical Properties of the Titanium Flange Nut with 6 Points

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition of Titanium Flange Nut with 6 Points

| Grade | Fe (Max %) | O (Max %) | N (Max %) | C (Max %) | H (Max %) | Pd (Max %) | Al (%) | V (%) | Ni (Max %) | Mo (Max %) |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | — |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | — |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | — |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | — |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | — |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | — |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | — |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | — |

| Ti | Balance |

Applications of the Titanium Flange Nut with 6 Points

Titanium Flange Nuts with 6 Points are among the most widely used high-performance fasteners. They are primarily used to secure and lock components together in environments requiring lightweight, high-strength, and corrosion-resistant materials.

Typical applications include:

Aerospace: Jet engines, structural components, and spacecraft assemblies

Automotive: Racing vehicles, high-performance engines, and exhaust systems

Marine: Offshore structures, shipbuilding, and seawater pipelines

Industrial: Chemical equipment, heat exchangers, and pressure vessels

Medical and Electronics: Devices requiring non-magnetic and biocompatible materials