-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

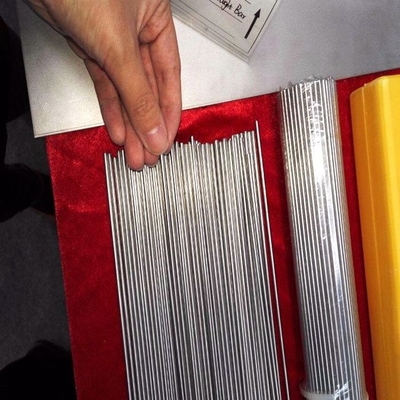

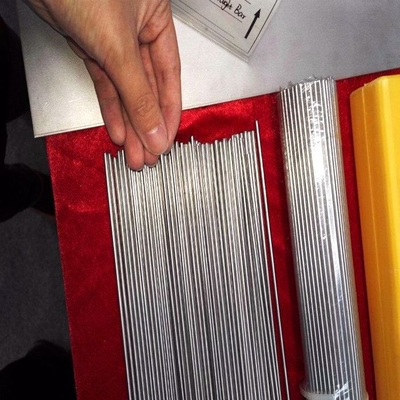

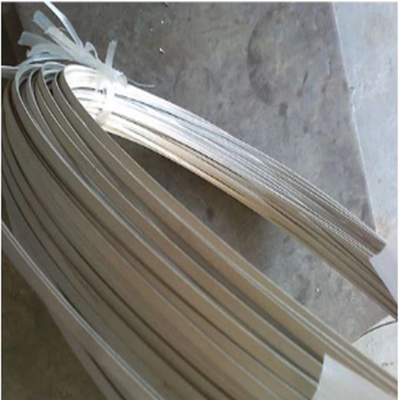

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

AWS A5.16 ErTi-2/ErTi-5 Titanium welding Wire supplier industrial

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium | Grade | Grade 1,Grade 5, Ti-6al-4v,grade 2,grade 4,grade 23,grade 7,grade 11 |

|---|---|---|---|

| Diameter | 0.05-3mm | Surface | Polished, Pickling,Anodizing |

| MOQ | 10kg | Color | Silver, Black,pickling |

| Technical | Cold Drawn,welding | Delivery Time | 7-10 Days |

| Highlight | ASTM B348 Titanium Filler Wire,Ti6al4v Titanium Filler Wire,Pickling titanium coil wire |

||

Description

Titanium wire is a high-performance material known for its low density, high strength, and excellent corrosion resistance. It is widely used in TIG welding, anodising, chemical processing, medical applications, and aerospace industries.

Titanium wire can be supplied in various forms—coiled wire, straight wire, or TIG rod lengths—depending on the application. It is ideal for tying, clamping, and welding in demanding environments where strength-to-weight ratio and corrosion resistance are critical.

Specifications

| Property | Details |

|---|---|

| Material | ERTI-2 / ERTI-5, Grade 1, Grade 2, Grade 4, Grade 5, Grade 7, Grade 12, Grade 23 |

| Standard | ASTM B863, AWS A5.16, ASTM B348 |

| Color | Silver, Black, Pickling |

| MOQ | 10 kg |

| Diameter | 0.05 – 3.0 mm |

| Surface Finish | Polished, Pickling, Anodising |

| Shape | Coiled Wire / Straight Wire |

| Keywords | Chinese Titanium Valley, Titanium Welding Wire |

| Applications | TIG Welding Wire, Anodising Rack Tie Wire, Dental Appliances, Safety Wire, Pressure Vessel Fabrication |

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition

| Grade | Fe (Max) | O (Max) | N (Max) | C (Max) | H (Max) | Pd (Max) | Al (%) | V (%) | Ni (Max) | Mo (Max) | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | — | Balance |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | — | Balance |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | — | Balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | — | Balance |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | — | Balance |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | — | Balance |

Key Features

Excellent corrosion resistance in seawater, acids, and alkalis

High strength-to-weight ratio

Non-toxic, biocompatible (suitable for medical and dental use)

Non-magnetic and thermally stable

Excellent weldability and formability

Applications

Welding: TIG/MIG welding of titanium and titanium alloy components

Chemical Industry: Electrodes, anode/cathode racks, and tie wires for anodising

Medical: Dental appliances, implants, and surgical instruments

Aerospace: Fasteners, springs, and safety wire

Industrial: Pressure vessel fabrication, heat exchangers, and filtration supports

Quality Assurance

A. Produced using 100% titanium sponge and three-time melting to ensure uniform chemical composition.

B. Chemical composition tested at each production stage—from ingot to finished product.

C. Strict process control and full traceability for every batch.

D. Certified according to ISO 9001:2015 standards.